cnc die sinking edm machine DMNC-EDM is a well-experienced professional manufacturer and supplier of CNC EDM machine including die sinking machine, wire cut machine, small hole EDM drilling machine and EDM parts. Inquiry now! +86-13914052243

To install a junction box in the attic, you will need the following materials and tools: Junction Box: Select a junction box that meets the requirements of your electrical project, taking into account the size, material, .

0 · sinker edm shops

1 · sink edm services near me

2 · mitsubishi wire edm machines

3 · mitsubishi wire edm epack list

4 · mitsubishi electric electrical discharge machines

5 · mitsubishi edm wire cut machine

6 · charmilles edm machine cost

7 · best edm sinker machine

The size used should equate to the current rating of the circuit being connected into - you can always use a higher rated box than the circuit but never a lower rated box. For a lighting circuit use a 20amp junction box and for a ring main or radial circuit use a 30 amp junction box.

With excellent performance, the EDM CNC die sinker machines are suitable for processing small and medium-sized precision plastics and die-casting molds, especially for .CNC die sinking EDM is a high-precision machining equipment widely used in .DMNC-EDM is a well-experienced professional manufacturer and supplier .

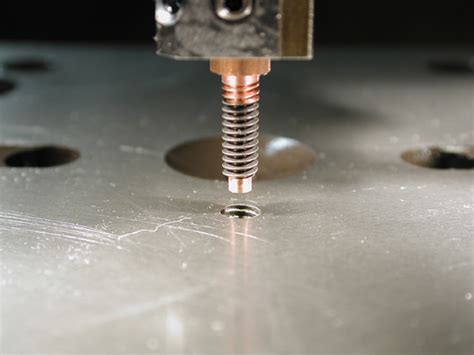

CNC die sinking EDM is a high-precision machining equipment widely used in mold manufacturing, aerospace, automotive parts, and other fields. Understanding its principles and .Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subjec.DMNC-EDM is a well-experienced professional manufacturer and supplier of CNC EDM machine including die sinking machine, wire cut machine, small hole EDM drilling machine and EDM parts. Inquiry now! +86-13914052243

The new AL40G, AL60G and AL80G are the next-generation die-sinker EDM that fuses discharge control technology carefully nurtured since the foundation of the company, advanced flat rigid linear motor control technology developed over .With any sinker EDM machine, you need to be sure your tool will get the job done. With tight profit margins, every saved minute is another dollar in your pocket. Choose a tried and tested CNC EDM machine sold by trusted .

From our die-sinking cutting EDM machines and high-precision machining components, to mold making as well as electrical discharge and spark erosion processes, our CNC and sinker EDM solutions position you for success.CNC DIE SINKER key features: Sodick supported system & Touching screen. G-Code processing & Auto expert database.EXCETEK EDM provide MOSFET sparking circuit where it sustains only less electrode wear and fast erosion speed which can achieve minor erosion with smooth surface roughness.

sinker edm shops

Nantong New Era Technology Co., Ltd: New Era has specialized in the design and production of CNC machine tools for more than 20 years. Its products include EDM machines, engraving . With excellent performance, the EDM CNC die sinker machines are suitable for processing small and medium-sized precision plastics and die-casting molds, especially for cosmetics molds, high-end toy molds, molds of medical products, carbide .CNC die sinking EDM is a high-precision machining equipment widely used in mold manufacturing, aerospace, automotive parts, and other fields. Understanding its principles and working processes is crucial for efficient use of this equipment.Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1]

DMNC-EDM is a well-experienced professional manufacturer and supplier of CNC EDM machine including die sinking machine, wire cut machine, small hole EDM drilling machine and EDM parts. Inquiry now! +86-13914052243The new AL40G, AL60G and AL80G are the next-generation die-sinker EDM that fuses discharge control technology carefully nurtured since the foundation of the company, advanced flat rigid linear motor control technology developed over 20 years, and the latest artificial intelligence (AI).

With any sinker EDM machine, you need to be sure your tool will get the job done. With tight profit margins, every saved minute is another dollar in your pocket. Choose a tried and tested CNC EDM machine sold by trusted machine tool distributors.

From our die-sinking cutting EDM machines and high-precision machining components, to mold making as well as electrical discharge and spark erosion processes, our CNC and sinker EDM solutions position you for success.CNC DIE SINKER key features: Sodick supported system & Touching screen. G-Code processing & Auto expert database.EXCETEK EDM provide MOSFET sparking circuit where it sustains only less electrode wear and fast erosion speed which can achieve minor erosion with smooth surface roughness.

Nantong New Era Technology Co., Ltd: New Era has specialized in the design and production of CNC machine tools for more than 20 years. Its products include EDM machines, engraving and milling machines and various machining centers. With excellent performance, the EDM CNC die sinker machines are suitable for processing small and medium-sized precision plastics and die-casting molds, especially for cosmetics molds, high-end toy molds, molds of medical products, carbide .

CNC die sinking EDM is a high-precision machining equipment widely used in mold manufacturing, aerospace, automotive parts, and other fields. Understanding its principles and working processes is crucial for efficient use of this equipment.Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1]

sink edm services near me

DMNC-EDM is a well-experienced professional manufacturer and supplier of CNC EDM machine including die sinking machine, wire cut machine, small hole EDM drilling machine and EDM parts. Inquiry now! +86-13914052243The new AL40G, AL60G and AL80G are the next-generation die-sinker EDM that fuses discharge control technology carefully nurtured since the foundation of the company, advanced flat rigid linear motor control technology developed over 20 years, and the latest artificial intelligence (AI).With any sinker EDM machine, you need to be sure your tool will get the job done. With tight profit margins, every saved minute is another dollar in your pocket. Choose a tried and tested CNC EDM machine sold by trusted machine tool distributors.From our die-sinking cutting EDM machines and high-precision machining components, to mold making as well as electrical discharge and spark erosion processes, our CNC and sinker EDM solutions position you for success.

CNC DIE SINKER key features: Sodick supported system & Touching screen. G-Code processing & Auto expert database.EXCETEK EDM provide MOSFET sparking circuit where it sustains only less electrode wear and fast erosion speed which can achieve minor erosion with smooth surface roughness.

stainless steel recessed specimen pass thru cabinet

stainless steel plate rack cabinet

Surface finishes and treatments play a critical role in enhancing both the functionality and aesthetics of CNC machined parts. Choosing the right finish or treatment can improve the wear resistance, corrosion resistance, and overall longevity of the part.

cnc die sinking edm machine|mitsubishi wire edm epack list