cnc machine ball screw A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball . Can you install a vanity light without a junction box? For example, if you have a light fixture that doesn't need a box for mounting, but the wiring connections are not protected by some kind of cover, then you can't use the fixture without a junction box.

0 · standard ball screw sizes

1 · cnc router with ball screws

2 · ball screw vs belt drive

3 · ball screw size guide

4 · ball screw size chart

5 · ball screw selection guide

6 · ball screw manufacturing process

7 · anti backlash ball screw nuts

VERSATILE AND CREATIVE - The Sunlite Linear Bar Vanity Light Fixture is versatile in many ways! Providing illumination for task lighting above your bathroom mirror or bathroom sink. .

Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the .

Lead screws have sliding friction, and so you need more power to move the machine parts. Ball screws have rolling friction, like ball bearings, and so require less power .

standard ball screw sizes

cnc router with ball screws

Refer to the Ballscrew Backlash Test procedure that is appropriate for your machine. Power off and lock out the machine. Remove the necessary covers to access the . A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball . The main components of a ball screw are the screw assembly and the nut assembly. The screw and nut are machined with matching helical grooves large enough to hold ball bearings. The bearings are preloaded against the .Ball screws are used in a wide variety of industrial and high-tech applications. Some common examples include: Machine tools: Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other CNC .

At the heart of any CNC machine is its ability to convert rotational motion into linear motion with absolute precision. This is where ball screws come into play. Unlike traditional lead screws, .Ball Screw systems create improved wear and tear levels. The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a . What is a ball screw and why is the most common type used in CNC milling machines? The spindle is a mechanism designed to transmit motion to certain parts of the .Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the differences in their construction, performance, and applications.

Here’s a breakdown of how ball screw technology works and why it delivers better results for your CNC router. How ball screw technology works To understand ball screw technology, we need to start with two key components: the ball screw and the ball nut. Lead screws have sliding friction, and so you need more power to move the machine parts. Ball screws have rolling friction, like ball bearings, and so require less power and have longer. Refer to the Ballscrew Backlash Test procedure that is appropriate for your machine. Power off and lock out the machine. Remove the necessary covers to access the axis with the problem. Remove the axis motor cover. Install the coupler-installation tool [1] on the motor coupling.

A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball screws. Rack and Pinion Advantages : The main components of a ball screw are the screw assembly and the nut assembly. The screw and nut are machined with matching helical grooves large enough to hold ball bearings. The bearings are preloaded against the grooves of the screw to eliminate backlash.Ball screws are used in a wide variety of industrial and high-tech applications. Some common examples include: Machine tools: Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other CNC machines. Robotics: Ball screws are used in many robotic applications, including robotic arms and legs.

At the heart of any CNC machine is its ability to convert rotational motion into linear motion with absolute precision. This is where ball screws come into play. Unlike traditional lead screws, ball screws offer significantly reduced friction, leading to smoother, more accurate movements. Here’s why they’re so crucial:Ball Screw systems create improved wear and tear levels. The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a channel design. What is a ball screw and why is the most common type used in CNC milling machines? The spindle is a mechanism designed to transmit motion to certain parts of the milling machine or other heavy industrial machines through a .Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the differences in their construction, performance, and applications.

ball screw vs belt drive

Here’s a breakdown of how ball screw technology works and why it delivers better results for your CNC router. How ball screw technology works To understand ball screw technology, we need to start with two key components: the ball screw and the ball nut. Lead screws have sliding friction, and so you need more power to move the machine parts. Ball screws have rolling friction, like ball bearings, and so require less power and have longer. Refer to the Ballscrew Backlash Test procedure that is appropriate for your machine. Power off and lock out the machine. Remove the necessary covers to access the axis with the problem. Remove the axis motor cover. Install the coupler-installation tool [1] on the motor coupling. A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball screws. Rack and Pinion Advantages :

The main components of a ball screw are the screw assembly and the nut assembly. The screw and nut are machined with matching helical grooves large enough to hold ball bearings. The bearings are preloaded against the grooves of the screw to eliminate backlash.Ball screws are used in a wide variety of industrial and high-tech applications. Some common examples include: Machine tools: Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other CNC machines. Robotics: Ball screws are used in many robotic applications, including robotic arms and legs.

At the heart of any CNC machine is its ability to convert rotational motion into linear motion with absolute precision. This is where ball screws come into play. Unlike traditional lead screws, ball screws offer significantly reduced friction, leading to smoother, more accurate movements. Here’s why they’re so crucial:

Ball Screw systems create improved wear and tear levels. The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a channel design.

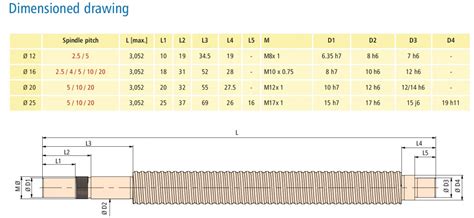

ball screw size guide

ball screw size chart

ball screw selection guide

ball screw manufacturing process

Even your old lunch box may be worth a pretty penny. You may be surprised how much vintage lunch boxes can go for on resale sites like eBay (think upward of $1,000). Below are 10 of the most valuable we’ve found.

cnc machine ball screw|ball screw manufacturing process