cnc lathe machine function The CNC lathe machine tool has revolutionized how materials are manipulated, making it an indispensable tool in various industries and many machine shops. Its ability to perform intricate cutting and shaping with . When talking about 5-axis machining, it is a more advanced technology over the traditional 3-axis version that has been utilized for decades. This particular model is able to move in five different directions, allowing machinists to have a .

0 · types of cnc lathe machines

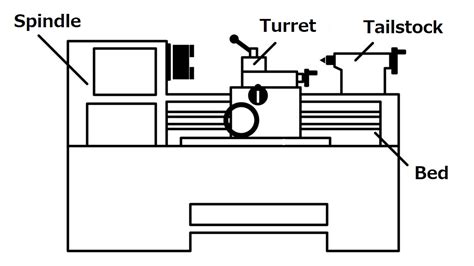

1 · lathe machine block diagram

2 · cnc lathe machine specification

3 · cnc lathe machine diagram

4 · cnc lathe machine description

5 · cnc lathe for beginners

6 · cnc lathe explained

7 · basics of lathe machine

K Factor in sheet metal bending is a constant used to calculate sheet metal .

CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries.

The CNC lathe machine tool has revolutionized how materials are manipulated, making it an indispensable tool in various industries and many machine shops. Its ability to perform intricate cutting and shaping with .CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries.

The CNC lathe machine tool has revolutionized how materials are manipulated, making it an indispensable tool in various industries and many machine shops. Its ability to perform intricate cutting and shaping with incredible precision makes it a cornerstone in modern manufacturing processes. What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though.

How Does a CNC Lathe Machine Work? Image Credits: marvo.eu. A simple CNC lathe operates by eliminating materials from a rotating workpiece with a cutting tool to create the required shape. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding and rotating a workpiece around a cutting tool. CNC lathe machine operations are many and varied, while results largely depend on the tools used with the machine.What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes. Understanding what is a CNC lathe machine reveals its significance in modern manufacturing processes and highlights why it has become an indispensable tool in workshops worldwide.

Welcome to our in-depth exploration of CNC lathe machine parts and functions. In this comprehensive guide, we will take you on a journey through the inner workings of a CNC lathe machine, providing detailed insights into the various components that make it function seamlessly.

CNC lathe machines offer advanced programming capabilities. Programming works by utilizing interactive on-screen programming packages or CAM packages that allow operators to select features, tools, speeds, feeds, and other parameters. There are several benefits to using CNC lathes for your machining needs, including: Increased precision: CNC lathes are capable of extremely precise movements and can make accurate cuts and shapes with high repeatability. This makes them ideal for producing complex parts with tight tolerances.CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries.

The CNC lathe machine tool has revolutionized how materials are manipulated, making it an indispensable tool in various industries and many machine shops. Its ability to perform intricate cutting and shaping with incredible precision makes it a cornerstone in modern manufacturing processes.

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though. How Does a CNC Lathe Machine Work? Image Credits: marvo.eu. A simple CNC lathe operates by eliminating materials from a rotating workpiece with a cutting tool to create the required shape. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding and rotating a workpiece around a cutting tool. CNC lathe machine operations are many and varied, while results largely depend on the tools used with the machine.What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes.

Understanding what is a CNC lathe machine reveals its significance in modern manufacturing processes and highlights why it has become an indispensable tool in workshops worldwide.Welcome to our in-depth exploration of CNC lathe machine parts and functions. In this comprehensive guide, we will take you on a journey through the inner workings of a CNC lathe machine, providing detailed insights into the various components that make it function seamlessly. CNC lathe machines offer advanced programming capabilities. Programming works by utilizing interactive on-screen programming packages or CAM packages that allow operators to select features, tools, speeds, feeds, and other parameters.

solid steel outlet box

types of cnc lathe machines

Standard North American junction boxes come in a variety of shapes and sizes (round, octagon, square, rectangular); however, most wiring devices intended for junction box mounting, save for light fixtures, are designed around the standard device yoke mounting pattern -- this is defined in NEMA WD-6 (an abridged version can be found here) as a 4 .

cnc lathe machine function|basics of lathe machine