fabrication sheet metal layout patterns Sheet metal fabrication is a complex process that involves designing, cutting, bending, and assembling sheet metal into a final product. However, even the most skilled designers can make mistakes that can lead to . Rivets are low-cost and come in a range of different materials like aluminum, stainless steel, and copper. This article will explain how rivets are typically installed, what materials are used, and describe some commonly used rivets. What is a .

0 · sheet metal formulas for layout

1 · sheet metal flat pattern layout

2 · sheet metal fabrication handbook pdf

3 · sheet metal development drawing pdf

4 · sheet metal design standards pdf

5 · sheet metal design guide pdf

6 · free sheet metal layout patterns

7 · free sheet metal layout books

L-shaped metal brackets, also called corner braces, create a secure 90-degree connection between two pieces of material. Widely used for shelves, furniture, and general construction, .

Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati. Triangulation is a practical approach to pattern development. Developing patterns is an essential part of sheet metal work. This is an introduction to the process. You will find . Sheet Metal Fabrication Tutorials. Written on 21 December 2008. How to develop a Square to Round. A true understanding of what "True Length" means and how to find and . Sheet metal fabrication is a complex process that involves designing, cutting, bending, and assembling sheet metal into a final product. However, even the most skilled designers can make mistakes that can lead to .

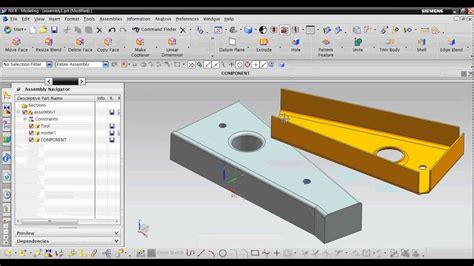

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and . Accurate Flat Pattern Layout: Inside Setback ensures that the flat pattern is dimensioned correctly, . Practical Applications in Custom Sheet Metal Fabrication. Using these design formulas will ensure that your sheet metal .The following videos were created to help Apprentices and Mechanics affiliated with the International Association of Heat and Frost Insulators and Allied Workers Union to perfect their skills at specific, advanced metal layouts. If you have any questions about executing these metal cuts, please contact your Local Union JATC Training Coordinator.

Study with Quizlet and memorize flashcards containing terms like When making a sketch of a component what information should be included?, What layout method is used to develop patterns for rectangular, round, and square ducts?, When constructing an elbow how many gores will reduce air flow resistance the most? and more.Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number .sheet-metal layout and fabrication is provided. SHEET-METAL LAYOUT AND CUTTING TOOLS AND EQUIPMENT Numerous types of layout tools, cutting tools, and forming equipment are used when working with sheetReview this sheet metal layout tip on why you should not dimension in the flat pattern and instead always dimension to the . This is a common occurrence when manufacturers receive a sheet metal layout dimensioned in the flat pattern. These dimensions may seem helpful, but after your manufacturer makes bend deductions based on their .

Well-known and respected handbooks by Richard Budzik include sheet metal layout handbooks for ductwork (HVAC), precision sheet metal or metal fabrication handbooks, and ductwork templates. Practical Publications, LLC 262-620-1408 354 US Highway 89 Vaughn, MT 59487. Order direct from the publisher - Practical Publications! .i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" that the part in the drawing could be made from a single non-overlapping sheet of metal. basically it was a .

Getting the flattened pattern of sheet metal fabrication parts by hand is time consuming, requires lots of knowledge, and it is prone to errors and not reliable.. There are lots of good sheet metal pattern development software programs out there, but they are expensive, with high subscription fees, with complex hardware requirements, and extensive user knowledge.Fabrication Two – Radial Line Development (55 Hours) Trainee ISBN 978-0-13-609933-8 Instructor ISBN 978-0-13-609908-6 (Module ID 04203-08) Introduces radial line development principles used to determine layouts for sheet metal fittings. Includes practice layout and fabrication tasks that allow trainees to develop and demonstrate their .Sheet Metal Pattern Layouts NAVDOCKS. Power Distribution Network Design for VLSI Sheet Metal Layout Simplified Metal Forming Handbook . 2 Formulas For Sheet Metal Layout And Fabrication 2024-05-27 Aviation Administration (FAA) Flight Standards Service. It .Volume 6: Sheet Metal Layout and Fabrication. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. When making a sketch of a component what information should be included? All needed descriptive information. 1 / 50. 1 / 50. . Metal patterns that are .

Sheet Metal Pattern Layouts. by Edwin Anderson | Jan 1, 1943. 4.7 out of 5 stars. 5. Hardcover. . with practical and modern methods for laying out and forming patterns for round and . formulas applies to sheet-metal work. by Joseph J Kaberlein | Jan 1, 1947. 4.8 out of 5 stars. 6. Hardcover. . Practical Sheet Metal Layout: Fittings Used .Sheet metal fabricators can “unbend” the model on their end to produce the part to specifications. In some cases, a DXF file can be used for both . DXF files may also be used as a flat-pattern (blanking) reference when building a bent sheet component. You can get an instant quote using DXF files from Xometry by uploading and specifying theSheet Metal Pattern Layouts Bookreader Item Preview . Layout dc.subject.keywords: Shape dc.title: Sheet Metal Pattern Layouts. Addeddate 2017-01-17 20:55:49 Identifier in.ernet.dli.2015.16712 Identifier-ark ark:/13960/t67429681 Ocr ABBYY FineReader 11.0 .

Sheet Lightning: Sheet Metal Unfolding Software for Ducts, Flue, Chutes, Chimneys, Hoppers, Structural Steel etc: Shareware. LITIO: 3D Sheet Metal Unfolding software: Shareware. SolidWorks Explorer: File manager for SolidWorks files, similar to Windows ExplorerSheet metal fabrication involves cutting and shaping operations. True. Sheet metal is trimmed with squaring shears. True. Sheet metal workers can remain current in the field by _____. 1) reading trade publications 2)attending classes and seminars 3)participating in professional or trade organizations.Development Cord Length has calculated by this calculator and Denoted By X1 and X2. This development Angle is used to layout cone fabrication layout markings or Flat Pattern Markings. Refer to Standard Image for understanding these dimensions at Output sections. What are Types of Cone Flat Pattern Layout Available with this Cone Calculator

Sheet metal layout and fabrication is a vital skill for professionals in various industries, including construction, automotive, and aerospace. . The primary goal of sheet metal layout is to accurately plan and create a flat pattern that can be bent, folded, or otherwise manipulated into the desired 3D shape. To achieve this, you must . Study with Quizlet and memorize flashcards containing terms like When making a sketch of a component what information should be included?, What layout method is used to develop patterns for rectangular, round, and square ducts?, When constructing an elbow how many gores will reduce air flow resistance the most? and more. It introduces the learner to the techniques used in parallel line, radial line, and triangulation. With videos and animations, the learner has an opportunity to play, pause, and rewind as they practice these techniques. This book covers material required for a level 1 sheet metal apprentice (Line E).Sheet metal parts are used in countless commercial and military products. Sheet metal parts are found on almost every product produced by the metalworking industries throughout the world. Sheet metal gauges run from under 0.001 in to 0.500 in. Hot-rolled steel products can run from in thick to no. 18 gauge (0.0478 in) and still be considered sheet.

wooden swing set metal brackets

Our guide offers a comprehensive list of 71 key terms and definitions to help you navigate the world of sheet metal fabrication with confidence. . Refers to the process of printing text or patterns on the surface of a workpiece using special ink. The output must be free of defects, such as adhesion, resistance to organic solvents, chromatic .This Unique 70 Days " Master In Fabrication Layout " Course will Turn you to Become Expert in Flat Pattern Fabrication Layout Development of All Shapes used in Process Equipment Fabrication, Sheet Metal Fabrication, Ducting Fabrication and Insulation Industry even if you just starting your career in the Field of Fabrication.Conclusion: Continuous Improvement and Future Trends in Sheet Metal Layout---Mastering Sheet Metal Layout: Efficient Patterns & Techniques Introduction: The Importance of Efficient Sheet Metal Layout In the world of manufacturing, sheet metal fabrication plays a crucial role across diverse industries, from automotive and

Sheet Metal Layout Patterns Sheet Metal Pattern Layouts AbeBooks. sheetmetal pattern layout eBay. Catalog Record Sheet metal pattern layouts a practical. . The Art And Science Of Bending Sheet Metal Hackaday. Chapter 13 Layout and Fabrication of Sheet Metal and. Sheet Metal Cone Layout Calculator pdfsdocuments2 com. Cone Calculator Chicago .Getting the flattened pattern of sheet metal fabrication parts by hand is time consuming, requires lots of knowledge, and it is prone to errors and not reliable.. There are lots of good sheet metal pattern development software programs out there, but they are expensive, with high subscription fees, with complex hardware requirements, and extensive user knowledge.

sheet metal formulas for layout

sheet metal flat pattern layout

sheet metal fabrication handbook pdf

Conduit junction boxes are made from a variety of materials, including metal and plastic, and they come in different types and sizes to suit specific needs. Let’s explore these aspects in more detail. The most common type is the electrical .

fabrication sheet metal layout patterns|sheet metal formulas for layout