tolerance on cnc parts Common Tolerances in CNC Machining. Engineering tolerances are a necessary requirement when defining product measurements. Unless . Yes, it is possible to turn a metal garage into a home depending on the size of the structure and local zoning laws. It would likely involve replacing the existing metal walls with drywall or other materials to improve insulation, as well as adding windows and a .

0 · typical tolerances of manufacturing processes

1 · typical cnc machine tolerance

2 · standard tolerance chart for machining

3 · milling tolerance chart

4 · machining tolerances chart

5 · iso machining tolerance chart

6 · how accurate are cnc machines

7 · cnc tolerance standards

Bento-style lunches are easy with our ECO+ Lunch-It® boxes. Set includes two containers, each with one 1⅓-cup/340 mL and two ⅓-cup/105 mL separated compartments and airtight seals.

Also, be aware that these are bilateral tolerances. If expressed in unilateral terms, the standard tolerance would read +0.000/- 0.010 in. (or +0.010/- 0.000 in.) while a limit-basedtolerance in our bracket example would be 1.005 / 0.995 in. All are acceptable, as are metric values, provided that you spell them . See moreThere’s more to part tolerancing than length, width, hole size, etc. There’s also surface roughness, which in the standard offering is equal to . See moreHere’s another consideration. As mentioned earlier, we can accept GD&T tolerancing. This provides a deeper level of quality control that includes relationships between various part features as well as form and fit qualifiers. Below are a few of . See more

electric switch box wiring

Common Tolerances in CNC Machining. Engineering tolerances are a necessary requirement when defining product measurements. Unless .Contents hide 1 Machining Tolerances 101: A Complete Guide to CNC Machining Tolerances 1.1 General Tolerances of Linear and Angular Dimensions 1.2 Geometric Tolerances 1.3 Classification of Shape Tolerances 1.4 .

I think the tolerance block is kind of sitting there like a watermark on the page, the designer doesn't even regard it. For example, I see drawings for mill and for lathe turned parts with the exact same tolerance block (like x.xxx=+/-.005") and anyone with a lick of sense knows that if you crank out lathe turned parts at +/-.005, nobody is going to be happy with what you're .Fine-tuning tolerance dimensions in your designs for CNC machined parts can help maximize those parts’ quality and reduce cost. Tolerancing guidelines for CNC machining Over constraining a design can take two forms: either adding .These tolerances are crucial in CNC machining, as they ensure that parts fit together correctly and operate as intended, while also accounting for the inherent limitations of the machining process. Tolerances are typically specified as a plus/minus value, ±0.01 mm, indicating the acceptable variation in the final dimensions.

Beyond enhancing product integrity, a strict tolerance CNC machining process brings efficiency gains to the manufacturing workflow. High-precision CNC machines can produce parts faster while reducing material wastage, saving time, and cutting costs which directly benefits the client with speedier lead times and lower prices. The phrase CNC milling tolerances refers to the permissible limits of variation in the dimensions of parts produced by CNC milling machines. CNC milling tolerances dictate how much a part’s measured dimensions can deviate from the design specifications and still be considered acceptable.

ISO 2768 comes in two parts — ISO 2768-1 and ISO 2768-2. These parts define mechanical precision levels to simplify technical drawings. . Standardization) created ISO 2768 as an international manufacturing standard that simplifies drawing specifications for CNC machining tolerances.What is the tolerance of CNC in general? General CNC machining tolerances typically range from ±0.1mm to ±0.05mm. This can vary based on the machine’s capability, the material, and the part’s complexity. How can I ensure my CNC parts meet specified tolerances? To ensure CNC parts meet specified tolerances, follow these practices: CNC Machining HDPE Plastics Parts. CNC machining is a plastic manufacturing process involving cutting tools mounted on a CNC machine and controlling them using g . Precision and Tolerance. CNC machining is a better alternative to traditional machining for engineering plastics like HDPE and PEEK because it can produce parts with complex .If it is still functional at 1,1mm, then that should have been the tolerance on the print instead because it's a real waste if functional parts are scrapped because the tolerances was overly tight. On non-mating faces, the tolerances could be dictated by available space, mass restrictions or the needed strength or stiffness of the part.

Most of our high volume parts the tolerance block is something like .xx is +/-.03, .xxx is +/-.010, and .xxxx is +/-.0010. These are pretty simple to set up and be able to leave to button pushers. Then we do a lot of tighter tolerance short order stuff. 5. Limit Tolerances. A limit tolerance is expressed as a range of values, where the part is fine as long as the measurement falls between that range. 13 – 13.5mm for example is a limit tolerance for CNC machining indicating that the part must have a measurement that falls between the upper and the lower limit (13mm is the upper limit and 13.5mm is the lower limit).

Methods for controlling tolerance of CNC parts. Tolerance control of CNC parts is the key to accuracy. Here are some ways to control the tolerance of CNC parts: Rational design. In the process of parts design, we must consider the machining characteristics of CNC machine tool, reasonable design of the size and shape of the parts.

We can deliver CNC machined plastic parts with tolerances as tight as +/- 0.0005 inches, depending on the part material and processes used. Our development process, which all parts go through, will find the best combination of cutting tools, annealing, and coolant to maintain close tolerances. Tight tolerance CNC machining is a manufacturing process that ensures components are produced with extremely high precision. This process is crucial for applications requiring tolerances as small as 1 micron. Industries . Why Machining Tolerances are Important? Understanding and controlling machining tolerances is crucial in the manufacturing industry. Here’s why: Quality Assurance. CNC machining tolerances ensure that parts are .

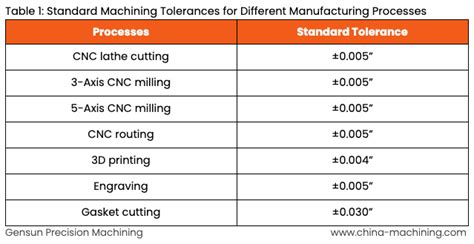

These are industry acceptable tolerances, so these would be accepted across multiple customer bases. and they’re accepted by manufacturers alike, these are relatively agreed upon. for the most part with CNC, the general guideline is plus or minus five-thousandths of an inch, that’s about the thickness of a sheet of paper. this chart here is .I would like the fit to be as snug as possible, without making the parts ridiculously expensive to make. I would like to know how much it costs to make the parts with 0.005 tolerance vs. 0.003 tolerance vs 0.001 tolerance. If it's only a little more, then it may be worth the extra cost to make the parts fit nice and snug.Trying my hand at making a CNC easy-build bedframe. Either 18 or 21mm ply. Wondering how much play I should add to the joints (box, mortice&tenon, and slots) to compensate for the potential variance in thickness, and to make things easy to assemble and disassemble by hand (but not be too sloppy).

Standard tolerances also help to shorten machine time when working with standard parts, and promotes a cost-effective way to manufacture parts. If a part will still work and function when machined within a tolerance range, then it can save the machinists and ordering company lots of money that may be incurred when obsessing with dimensional .CNC Machining +.005”/-.005” local tolerances across most geometries in metals, +/- 0.010" for plastics. Will vary for large parts, specifically when holding flatness over large parts after heat treatment. Finish requirements for “As Milled” finish will have a . Machined Parts: Ensuring precise angles on CNC machined components, such as the angle of a bevel gear or the slope of a ramp. Sheet Metal Fabrication: Controlling the bend angles in sheet metal parts, ensuring proper alignment and fit. . Tolerance Zone: The tolerance zone for angularity is not defined in angular units (degrees or radians) but .

Tolerance is critical in the design and manufacturing of CNC parts, to determine the tolerance value for a specific workpiece, we need the help of some international standards. Here we introduce ISO 2768 standard and ISO 2768 tolerance chart, also provide a free PDF file of General Tolerances for Linear and Angular Dimensions for download.

Different Types of Machining Tolerances. 7 Min MinTolerances in CNC machining are expressed in different ways, due to the different geometries of parts and the different types of machining processes. Let us go through these different tolerances one by one: Unilateral Tolerance Unilateral tolerances in CNC machining hint that the allowable variance can only occur in one . Design and Tolerance Considerations for CNC Machined Parts. For engineers, there are a number of things to keep in mind when designing and defining tolerances for CNC machined parts. Outside of part functionality and durability, it’s important to design your part for the manufacturing process. You’ll want to consider factors like:

The normal tolerance is absolutely not 0.1mm. Maybe that’s the title block tolerance on dimensions where it’s not otherwise specified, but tolerances are 100% of the time selected to interface with mating parts. Tolerance literally means “this part will tolerate of xx.x ± 0.X and still work in the assembly.” When it comes to CNC machined parts, the concept of a wall being “too thick” is less discussed compared to walls being too thin. . Cost, and Tolerance. To balance machining time, cost, and design accuracy, it’s advisable to maintain a minimum wall thickness of 0.06 (60 thousandths of an inch). If your part has deep pockets, a thicker .

typical tolerances of manufacturing processes

At Twiggs, you can “get it all in one call”. We’ve got the right tools for the job, at .

tolerance on cnc parts|standard tolerance chart for machining