tolerance of cnc machines Now that we understand why we need tolerance limits and its various types, let’s look at why selecting the right limit is important. The appropriate tolerance limit ensures flawless part . See more Metal fabrication comprises a number of processes used to manipulate flat metal into various shapes and structures. Forming, bending, cutting, punching, stamping, shearing, .

0 · typical tolerances of manufacturing processes

1 · typical cnc machine tolerance

2 · standard tolerance chart for machining

3 · machining tolerances chart

4 · how accurate are cnc machines

5 · cnc tolerance chart

6 · cnc machining tolerance chart

7 · cnc machine tolerance standards

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

While CNC machining servicesare highly accurate when it comes to product dimensions, they are not perfect. The final measurements between any two parts made using the same manufacturing process even on the same CNC machine are always off by a small amount. It is impossible to create identical . See moreEngineering tolerancesare a necessary requirement when defining product measurements. Unless the customer specifies any certain tolerances, the parts will usually be made . See more

Now that we understand why we need tolerance limits and its various types, let’s look at why selecting the right limit is important. The appropriate tolerance limit ensures flawless part . See more

CNC turning and millingare known for the high quality and precision they can provide. At the same time, engineers need to be wary of a few important aspects when choosing the . See moreStandardized Tolerances for CNC Machining. The standard prototype and production machining tolerance at Protolabs is +/- 0.005 in. (0.13mm). This means any part feature’s location, width, length, thickness, or diameter will not .

Read on to learn more about the concept of machining tolerances, how they are measured and calculated, and the different types of CNC machining tolerances. What is Machining Tolerance? Machining tolerance, also known . Using CNC machining, tolerances can be made even more accurate, with some machines capable of achieving ±0.0000984 inch (about ±0.0025 mm). To achieve this level of precision, CNC turning and milling .

typical tolerances of manufacturing processes

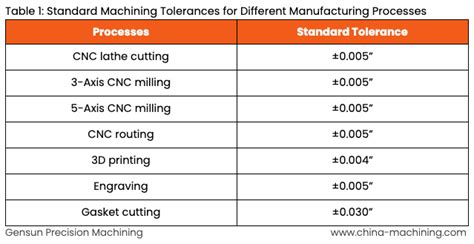

Common CNC Machining Tolerances. CNC machining is a wide field with many different processes under its umbrella. The CNC machining tolerances for each of these processes are different due to variations in the .

Contents hide 1 Machining Tolerances 101: A Complete Guide to CNC Machining Tolerances 1.1 General Tolerances of Linear and Angular Dimensions 1.2 Geometric Tolerances 1.3 Classification of Shape Tolerances 1.4 Classification of Geometric Positioning Tolerance 1.5 Conclusion 1.6 Richconn, Your Professional CNC Machining Services Partner Machining .CNC machining tolerances are the allowable deviations from the specified dimensions of a part. They define the range within which the actual measurements of a part can vary while still being acceptable. Tolerances ensure that parts fit together correctly and function as intended, maintaining the quality and reliability of the final product. .

Machine tolerances: Depending on the type of CNC machine, they also have their own restriction and range of achievable accuracy while machining. Generally, CNC machines are capable of maintaining a tolerance of ± 0.0025mm(Fan J, 2021) Tolerancing is crucial when parts are assembled later to make a specific product.

CNC machines can achieve very high levels of accuracy. Some machines can achieve accuracies as high as +/-0.0025mm. However, running the milling of a part on a CNC machine’s highest level of accuracy is an expensive and time-intensive undertaking. This is where CNC machining tolerances come in.

typical cnc machine tolerance

What are CNC Machining Tolerances? The tolerance of a cnc machined part is simply the amount of variation allowed in the dimension of the final manufactured part. This indicates the level of precision required for the part. Engineers specify tolerance by setting two values known as the upper and lower limits of the part’s dimension.

The Technology Behind Zero Tolerance Machining. Achieving such tight tolerances requires a combination of cutting-edge technology and highly skilled operators. Some key elements include: Advanced CNC Machines: Computer Numerical Control (CNC) machines with high-precision capabilities are the backbone of zero tolerance machining. These machines . CNC machining tolerances are essential for achieving the desired precision and accuracy in manufactured parts. This comprehensive guide delves into the various aspects of CNC machining tolerances, providing detailed insights into their calculation, types, and importance. Understanding these tolerances is crucial for producing high-quality components .

Machine Tool Capability: The capacity and precision of the CNC machine in use are instrumental in defining the range of achievable tolerances. High-quality machines, often with better stability, calibration, and feedback systems, can achieve tighter tolerances than older or less sophisticated machines.Most CNC machines can position down to around 0.005. You don't want your entire part to be that tight of a tolerance, because it greatly restricts the processes available, makes it more complicated and expensive to measure and means that even a tiny mistake or a microscopic chip on an end mill will scrap the part.

CNC machining tolerances are important parameters when manufacturing products, no matter their intended applications. Nowadays, most industrial and consumer products require consistency to meet manufacturing standards. Hence, product manufacturers rely on types of CNC machines for high accuracy in their manufacturing projects. However, it is . Standards for CNC Machining Tolerances. Tolerances, like other machining aspects, are governed by some standards. International standards that define machining tolerances are: ISO 2768. This standard defines general tolerances for linear and angular dimensions, chamfers, and radii. It helps simplify the process by providing default tolerances .

Beyond enhancing product integrity, a strict tolerance CNC machining process brings efficiency gains to the manufacturing workflow. High-precision CNC machines can produce parts faster while reducing material .CNC machining tolerances are the allowable deviations from the specified dimensions of a part. They define the range within which the actual measurements of a part can vary while still being acceptable. Tolerances ensure that parts fit together correctly and function as intended, maintaining the quality and reliability of the final product. .A standard machine drawing tolerance block should mostly call for +- .03 (2 decimals) Should only go to +- .010 for something decently critical (3 decimals) Anything tighter the engineer has to manually enter on the drawing so thought is involved . A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . ISO (International Organization for Standardization) created ISO 2768 as an international manufacturing standard that simplifies drawing specifications for CNC machining tolerances. What is iso 2768 Creating this international standard and its implementation make designing and manufacturing more accessible and convenient.

standard tolerance chart for machining

In addition, CNC machining is faster than manual machining, and it can be automated to further increase efficiency.When choosing a CNC machining provider, it is important to consider their experience with your specific industry and application. In addition, be sure to ask about their capabilities in terms of accuracy, precision, and tolerance. A standard tolerance level of +/- 0.0050 in advanced CNC machining is enough for most components/parts. However, tight tolerance becomes the basic requirement for manufacturing precision parts. Machine tolerance defines the allowable variations in components’ physical properties and dimensions.

Understanding of Tolerances In CNC Machining. In CNC machining, tolerances are usually involved in two aspects. For instance:it is valid for CNC machines and design aspects. Tolerance in CNC Machines. Most of the CNC machines have a dimensional accuracy of ±0.0025 mm. This measurement is as thin as a human hair. CNC Machining tolerances refer to how close the actual dimensions of a part are to the intended or design dimensions. In other words, tolerance is a measure of how much variation in dimension is acceptable. With CNC machining, parts can be cut to tolerances as tight as ±0.001 inch, and sometimes even better.CNC machining is a crucial process . How Well Does CNC Machining Perform? CNC machining is one of the most popular manufacturing processes today. And this is primarily due to its high accuracy, precision, and tight tolerance range. In fact, with CNC machining, you can accurately create over 1000 units of identical parts while achieving tolerances as small as ±0.04 mm.There are machines that can hold tolerances that cannot be measured with anything but the best computer controlled measuring equipment. A caliper is only a rough measuring tool, many quality CNCs have a repeatability of 0.0002" or well under since they are controlled by a computer not a 200 pound gorilla, so good micrometers or a good CMM are at minimum required to measure .

Understanding and applying the correct tolerances in CNC machining is not just about following technical guidelines—it’s about ensuring that every part you produce performs reliably and fits perfectly within its assembly. By mastering the various types of tolerances, from general and limit tolerances to more complex geometric and surface .The design and manufacture of tolerance of cnc machines comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards. CNC machining of precision parts, workpiece clamping can complete reaming,boring,drilling,tapping Various processes such . Tolerances in Different Manufacturing Processes. Tolerances vary across different manufacturing processes, each of which has its strengths and limitations: CNC Machining: CNC machining offers highly controlled tolerances, often as tight as +/- 0.002 in. for production parts. This process is ideal for precision parts, especially in industries .

nuclear reactor dissimilar metal weld fabrication flaws cracks and defects

nrg box electrical

Aluminium sheets, extrusions, or castings are the basic building blocks of the process, which involves transforming these materials through manufacturing into finished goods. Several processes are involved in the aluminium fabrication process.

tolerance of cnc machines|typical cnc machine tolerance