solidworks sheet metal box overlap Amazing workaround for sheet metal parts with intentional interference (think spring clips). Check out our pvc birdhouse selection for the very best in unique or custom, handmade pieces from our garden decoration shops.

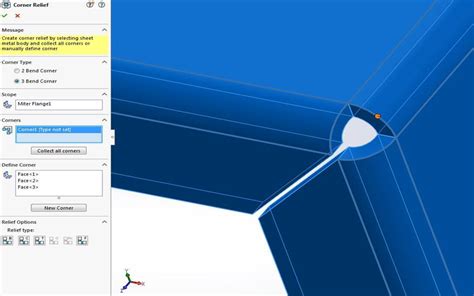

0 · solidworks sheet metal corners

1 · solidworks closed corners

2 · solidworks closed corner template

3 · solidworks closed corner properties

4 · solidworks closed corner extension

5 · sheet metal closed corner

High speed and high precision functions. Column elevation (bridge type or height block). For customized needs in the selection and use of accessories for the CNC vertical machining center VMC1060, contact us to learn more.

To close a corner: Create a sheet metal part that includes the area you want to close off. For example, you can use the closed corner feature to close off the open space between the adjacent, angled edge flanges. Click Closed Corner . Amazing workaround for sheet metal parts with intentional interference (think spring clips).You can apply corner treatments to a folded sheet metal body that will persist in the flattened state. You can view how the corner treatment impacts the folded sheet metal body and how it .Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . Overlap, Underlap: Defines .

Learn how to deal with sheet metal curvature overlaps when you have to cut large parts into seperate pieces to accomadate cutting machine max sizes.

In this video and blog, we will dig into one of the most powerful tools in SOLIDWORKS Sheet Metal that allows you to close corners.

I have attempted to assemble two folded sheet metal sections overlapping at the corner and then "cut extrude" using the sheet face but this creates varied results because of .

How do you overlap a sheet metal corner with closed corner. Hi all, I've been working on a sheet-metal model and I've gotten to the point of trying to close up the corners. For the corners I .When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .

You can apply corner treatments to a folded sheet metal body that will persist in the flattened state. You can view how the corner treatment impacts the folded sheet metal body and how it .Save Step File Multi-Body Sheet Metal Part, and split the oart completely from original part . All things related to Prusa 3D printers. Show off your prints, or ask a question. Pictures of boxes and shipping notices are considered low-effort and will be removed. . Why is the overlap between "people learning SolidWorks" and "people who know .

I have a couple parts with overlapping bends that are causing SolidWorks Sheet Metal to throw a fit. In order to hit all the required dimensions in the required material there is no avoiding the bends overlapping like I have shown below (I .

Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . Overlap, Underlap: Defines the rip type. Default gap for all rips: Defines the rip width. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness .Only parts with exact analytic cylindrical faces can be unfolded. As a test, try to insert an axis on the cylindrical face. If you can insert an axis, the model is an exact cylinder. If you cannot insert an axis, then the model is not an exact cylinder and cannot be unfolded.Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . Overlap, Underlap: Defines the rip type. Default gap for all rips: Defines the rip width. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness .

The name of the edge is displayed in the Fixed Face or Edge box. Set the Bend Radius. Select Ignore beveled faces to exclude chamfers from being converted into sheet metal bends. Under Bend Allowance, select from the following bend allowance options: . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness . Amazing workaround for sheet metal parts with intentional interference (think spring clips).Select Split (Features toolbar).; In the PropertyManager, under Trim Tools, select the sketch.; Click Cut Part.; Under Resulting Bodies, under , specify the bodies for the split operation.; Optionally, click the callout for each body and save it using the Save As dialog box.

Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . Overlap, Underlap: Defines the rip type. Default gap for all rips: Defines the rip width. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness .SOLIDWORKS 18 RIvet SHeet MetAL tOOLBOX PAge 18-1 Sheet Metal Toolbox Rivet A. Revolve. Step 1. Click File Menu > New, click Part and OK. . In the Dimension Modify dialog box: key-in .0686, Fig. 23 set config to This Configuration click Rebuild click OK . Step 8. Save. Use Ctrl-S. Fig. 17 Fig. 18 Fig. 19 Fig. 20 Fig. 21Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. Sheet Metal Gauge/Bend Table. Sheet metal gauge/bend tables store properties for a designated material.The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. I am trying to create a mandrel out of a sheet of LDPE that overlaps itself to create a cylinder. The overlap has velcro to keep its shape. I can't seem to get it to work, any suggestions? Attached is my sketch. . Creating sheet metal from spline.

2) Best Approach To Modeling Sheet Metal Bodies SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use theThe Base Flange and Edge Flange commands let you merge bodies in a multibody sheet metal part.. You can merge sheet metal bodies of the same thickness by: Using the Up to Edge and Merge option when inserting an edge flange between two bodies with parallel linear edges.; Using the Merge result option when adding a base flange that overlaps the profiles of multiple bodies .The Welded Corner PropertyManager allows you to add a weld bead to the corners of a folded sheet metal part, including miter flanges, edge flanges, and closed corners. Parent topicUsing Sheet Metal Tools. . SOLIDWORKS . NOTE: Without the radius the convert to sheet doesn’t work.Also something to note: the radius must be bigger than the metal thickness to work as well. Method 2: Creating Sheet Metal. Start off by making a sketch on the top .

Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . Overlap, Underlap: Defines the rip type. Default gap for all rips: Defines the rip width. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness .Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. . In the Check Entity dialog box, under Check for, select Minimum radius of curvature and click Check. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and .

The Bounding Box Nesting Preview displays the alignment drawing of the nested elements. The red dotted line is the sheet metal offset and the black dotted line is the bounding box offset.

Help Content Version: SOLIDWORKS Connected (3DEXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. In this video, I am going to explain about creating "Overlapping Cylindrical Sheet" in Solidworks-Sheet Metal.-----.You can create custom operations in the sheet metal template or in the CostingManager. . In the dialog box, click Custom and set options. Click Save. . Search 'Creating Custom Operations for Sheet Metal Parts' in the SOLIDWORKS Knowledge Base.If you use gauge tables to define the thickness of sheet metal parts, the gauge number appears in the Cut-List Properties dialog box. In the associated drawing, the gauge value is available for annotations and cut lists. Sensors. You can use sensors to alert you when sheet metal models deviate from the limits specified for a bounding box.

I have watched all the posts about creating a cone..but I can't seem to get the cone to overlap. The goal is to create the cone as a sheet metal part.add the holes for it to be riveted together and then flatten the part so it can be cut on a laser. . ©2002-2024 Dassault Systemes SolidWorks Corporation .So ive designed this part which started from a solid body, and i converted it all to sheet metal so it was in workable pieces for laser cutting, folding and welding. Issue is when i converted pieces to sheet metal, some overlap like this, and usually if i made this whole thing using the “Edge Flange” feature I could just edit the flange sketch, but in this case it was alot easier to model . CAD for sheet metal. December 4, 2017. After my anglegrinder cable got nibbled by mice I thought it might be a good idea to store it in a metal rather than cardboard box. I’ve made a few cardboard boxes in my time and to a lot of extent a sheet metal box is .

drawing a cone in sheet metal with overlap. SB By Sandeep Billakanti 06/17/19. Hi, I want to draw a cone top for one of my projects. The attached image shows the details of the cone. I also want the flat pattern of it. The material is 18GA Galvanized Steel. . ©2002-2024 Dassault Systemes SolidWorks Corporation .

cnc machine software free

Super simple to install without the need to disconnect cables in the majority of circumstances. Two part design allows backing plate to be installed behind existing connected cable using a single screw. Self locking slide on lid will prevent accidental opening .

solidworks sheet metal box overlap|solidworks closed corner properties