make own cnc machine Getting Started. Now that you’re aware of the factors to consider let’s dive into the steps to create your CNC machine: Design Your Machine: Start with a clear design. There are various online platforms like Fusion 360 or . Yes, you read it right, cutmen may use an enswell or face iron on a boxer’s face during a match! This small metal iron can come in different shapes depending on the body part it will be applied to: flat enswells for flatter regions .

0 · homemade cnc router machine

1 · homemade cnc milling machine

2 · home built cnc milling machine

3 · do it yourself cnc machine

4 · cnc machine for home hobbyist

5 · build your own cnc mill

6 · build it yourself cnc router

7 · best cnc machine for woodworking

CNC machines, short for Computer Numerical Control machines, are a manufacturing technology that utilizes a computer program and automated tools to perform subtractive manufacturing processes. Unlike 3D printers that .

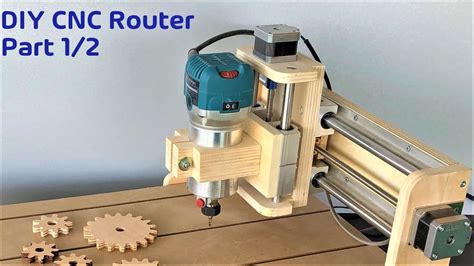

DIY CNC Router/Machine: How to Build Your Own. by Andreas Giencke. Updated Feb 6, 2023. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to .

For someone looking to get into a CNC build, [Old Tony]’s hard-won CNC experience really fills in the gaps left by other tutorials. And it looks like a . Getting Started. Now that you’re aware of the factors to consider let’s dive into the steps to create your CNC machine: Design Your Machine: Start with a clear design. There are various online platforms like Fusion 360 or .

This instructable shows all the steps I went through in designing and building this CNC router. The main thing I like about a CNC router, is that it is so versatile. . The best DIY CNC routers give you access to repeatable precision and reliability for your projects – without paying thousands of dollars for professional machines. My top choice for beginners is the Sainsmart .

How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel. My objective for this project was to design and build a CNC milling machine without the need.The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as well as size proved prohibitive. With this in . In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood. . I hope that these videos can support you in your own build. BooTec - Roman BooTec, Jun 8, 2019. ARKHAN_74 .After doing some research I decided to design and build my own machine. It took me almost 6 months to build and design the machine from start to finish. . I didn’t have that much experience with building CNC machines. This machine .

In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of. I decided to keep the vid.

How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.My MPCNC is a 3dprinted cnc and does timber and very light aluminium milling, around 500aud all up. if you want something that can do steel, the best would be get a milling machine like the sieg sx2.7 which is a very affordable milling machine, and add stepper motors and ball screws, you can also buy the conversion kit for it to save time. Making money with a CNC machine can be a lucrative business opportunity. CNC machines are used for precision machining tasks in various industries, including manufacturing, woodworking, and metalworking. Here are some ways to make money with a CNC machine:

How to build your own CNC machine from scratch. The exact assembly of your CNC machine will depend on the type of machine you choose to build, the custom options you choose, what you plan on making with the machine, and many other factors. Nevertheless, the key steps to build your own CNC machine will generally be as follows: 1. Design your machine

Build your own DIY CNC router kits 10. MPCNC – Mostly Printed CNC Machine Kit. Cost to build: 0-550 — More info here; Work Area: 500 x 300 x 81 mm; . A much larger-scale DIY CNC machine kit, the Root 4 is the newest and largest kit, with a 1204 x 1190 mm work area, and with 158 mm Z travel. .Build Your Own Cnc Machine: in this tutorial i'm going to show you how to make your own CNC machine. For this you can buy all the materials in local dealers, and electronic shops. CNC is a computer controled machine,and can cut, engrave and carve, in all kind of materials.I used 3D printing to make my own CNC machine V3! Share Add a Comment. Sort by: Best. Open comment sort options. Best. Top. New . You can use it to make a bigger CNC machine until the CNCeption is complete! Just don't ever look up "nsk robot module" on eBay and you're OK.These days, it's as simple as making a 3d model and sending it to a CNC mill for machining. Follow along on the journey of making your own custom coin (and a box to go with it). Materials. Brass stock; Screws; Tools. CNC milling machine capable of milling soft metals; 3D modeling software (Autodesk 123D Catch, optional) 2D photo editing .

In this video, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are .Acrylic is a very cheap durable material that cuts well on CNC. You could make custom license plate tags out of acrylic. My old engineering manager quit work cause it got to stressful and bought a laser to make custom license plate tags. Build A CNC Router For Your Own Shop! By: Chris Fitch Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. . But just as computers have gotten smaller, .

family circus metal lunch box

The latest cnc machines are controlled via gcode and grbl, repetier, or Marlin based controllers. Using mach 4 is a bit like using Windows to set up a file server.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisI've completed designs to build my own custom mainplate and bridges for a 6497 movement. The next step is milling the parts with a CNC machine that is good enough for the micro tolerances necessary for the movement to work. I've been doing research on desktop CNC mills, but I haven't found much information on the various watchmaking forums. .1. CNC Plasma Cutting Machine. 2. CNC Laser Cutting Machine. 3. CNC Milling Machine. 4. CNC Router Machine. 5. CNC Lathe Machine. Although plasma & laser cutting CNC looks similar but the differences between plasma,flame and laser cutting. CNC Flame cutting machine: it is a type cutting equipment that use gas with oxygen or gasoline in metal .

In retrospective materials are good enough for a cheap cnc machine and results are good but not optimal, accuracy is great but rigidity could be better. . Hardware store threaded rod makes a poor leadscrew, but it's not that hard to make your own CNC. Aluminum extrusions are convenient, but they're not required for CNC. Rectangular metal bar .Stepcraft makes a very good cnc. Axiom seems to make good machines. Hammer makes a good cnc. I have used an x-carve and have not been too happy with it. Maybe the x-carve pro is better. Avid does have good machines, but they are all kits, so it's only as good as you can put it together and that takes time and has its own cost.I then realized I had no place to put the CNC machine and it weighs in at 120 pounds, so I had to build a rolling base. Then after working with it briefly, I realized it made way too much dust and noise. I figured I could address both of those with a cover. I bought art foam board at the dollar store and created a hinged cover that tilts back.

As a result, using CNC machines for home décor is a popular idea and offers a host of CNC project ideas to sell, and even a great way to spruce up your own house too. Home and Business Signs. Download Example: Etsy; Designer: Casey Reames; Price: .50WHAT CAN YOU MAKE WITH THE X-CARVE PRO CNC MACHINE? AND MORE. ORDER NOW. SAVE TIME AND MONEY. No more skilled labor. No need to source and hire specialized operators. Our CNC system is so easy anyone can design and cut products. Return on Investment. We offer both personal and business financing options. Spread out costs of the X .after making body it's time to make a bed (flat surface) for placing paper on the machine. to make it I using cover of DVD writer which is made up of about 0.6mm thick sheet metal. mark a square of 70 x70 mm on it. and cut it using Angle Grinder. now put some hot glue on center part (moving part) of lens and stick the cut piece of sheet metal on it in such a way so that it can move .

Hi everyone! In this video I'll tell you how I made my CNC machine for a 3D treatment and material cutting. I needed this milling machine for a new project w. In many cases, that also includes headlight housing. While you can easily take off the headlights and paint the housing in any color, you can redesign and make a new housing if you own a CNC machine. That way, you can make something unique and improve the appearance of your car even more. 4. Suspension Components

homemade cnc router machine

vement of the STINGER weapon system components. It provides information to insure safe transport for worldwide mov. s of the system by air, highway, rail, and sea. Metric equivalent, .

make own cnc machine|do it yourself cnc machine