cnc machine cycle program First line Example: T1212 M06; G97 S400 M03; G76 P040060 Q100 R0.2 G76 X18.2 Z-18.0 P180 Q160 F1.5; G00 X25.0 Z10.0; The two-line G76 method gives us a bit more control over machining the thread, some versions of the FANUC controls allow us to use this style of thread cutting. The 'P' word gives us three . See more An instrument junction box is an enclosure housing terminals that allows interconnection between field devices (i.e. instruments, switches etc) in the process/production areas, and control or monitoring equipment typically located in the control room.

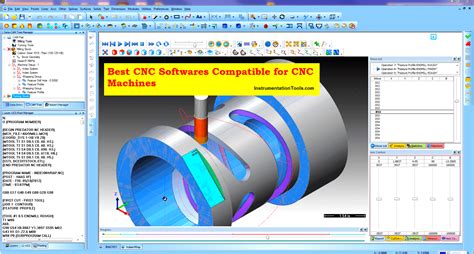

0 · top 10 cnc programming software

1 · different types of cnc programming

2 · cnc programming website

3 · cnc programming for dummies

4 · cnc milling programming for beginners

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for freshers

We find multiple types of junction boxes with their properties and advantages. For this reason, we categorize these electrical junction box types based on their features and applications. We will discuss each type in the .

top 10 cnc programming software

First line Example: T1212 M06; G97 S400 M03; G76 P040060 Q100 R0.2 G76 X18.2 Z-18.0 P180 Q160 F1.5; G00 X25.0 Z10.0; The two-line G76 method gives us a bit more control over machining the thread, some versions of the FANUC controls allow us to use this style of thread cutting. The 'P' word gives us three . See moreThe G32 screw thread cutting G-Code is not a canned cycle. It is used as a way to lock the rotation of the chuck to the pitch of the lead screw to enable us to have full control over the depth of each pass. It acts more like a G01 command where each line needs to be . See moreThe G92 is a screw cutting cycle that allows us to program the depth of each pass. It gives us full control over the X diameter for each . See more

I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function

different types of cnc programming

cnc programming website

G-code G76 is a cnc cycle which is used for thread cutting on cnc machines. G76 Thread Cycle can be used for Taper Threading, Multi-start thread cutting, .Here is a cnc programming example for simple drilling on a cnc lathe machine. CNC Fanuc control has a very powerful and versatile peck drilling cycle .The G72 facing cycle on a CNC lathe is a roughing operation that is used to cut along the X-Axis following the profile of the part.

Fanuc programming example which shows the use of multiple fanuc canned cycle in cnc programming, Following canned cycle are used in this cnc lathe programming example. This programming example also illustrate how G71 .

A good example of an operation that can be written directly with G-Code is the drilling cycle, so let’s dive in and look at how we can use the G81 drilling cycle on a CNC mill. Using G81 G81 is the standard drilling cycle that . In this article, we are going to dive into the world of drilling canned cycles and how we can program them using G-Code. Canned cycles are used when we are programming by hand to speed up the programming process. Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where .

Explanation of the different ways to cut a screw thread using not only the the G76 cycle but also G32 and G92 on a CNC lathe.I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function

3d printed cnc machine

G-code G76 is a cnc cycle which is used for thread cutting on cnc machines. G76 Thread Cycle can be used for Taper Threading, Multi-start thread cutting, Internal threading on cnc lathe. This G76 threading example actually cuts external threads on two different diameters.

Here is a cnc programming example for simple drilling on a cnc lathe machine. CNC Fanuc control has a very powerful and versatile peck drilling cycle (Fanuc G74) which relieves.The G72 facing cycle on a CNC lathe is a roughing operation that is used to cut along the X-Axis following the profile of the part.Fanuc programming example which shows the use of multiple fanuc canned cycle in cnc programming, Following canned cycle are used in this cnc lathe programming example. This programming example also illustrate how G71 turning cycle can be used for internal machining (boring operation). A good example of an operation that can be written directly with G-Code is the drilling cycle, so let’s dive in and look at how we can use the G81 drilling cycle on a CNC mill. Using G81 G81 is the standard drilling cycle that produces our holes with just a few lines of code.

In this article, we are going to dive into the world of drilling canned cycles and how we can program them using G-Code. Canned cycles are used when we are programming by hand to speed up the programming process. Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – .

Fanuc’s G71, G72, and G70 canned cycles are invaluable for lathe operations, particularly for internal machining such as boring and facing. These cycles automate the roughing and finishing processes, enhancing efficiency and precision. G71 is .Explanation of the different ways to cut a screw thread using not only the the G76 cycle but also G32 and G92 on a CNC lathe.I explain different G Code Cycles for CNC Lathe Programming in an easy to follow breakdown of each command and function

G-code G76 is a cnc cycle which is used for thread cutting on cnc machines. G76 Thread Cycle can be used for Taper Threading, Multi-start thread cutting, Internal threading on cnc lathe. This G76 threading example actually cuts external threads on two different diameters.

Here is a cnc programming example for simple drilling on a cnc lathe machine. CNC Fanuc control has a very powerful and versatile peck drilling cycle (Fanuc G74) which relieves.

The G72 facing cycle on a CNC lathe is a roughing operation that is used to cut along the X-Axis following the profile of the part.Fanuc programming example which shows the use of multiple fanuc canned cycle in cnc programming, Following canned cycle are used in this cnc lathe programming example. This programming example also illustrate how G71 turning cycle can be used for internal machining (boring operation).

A good example of an operation that can be written directly with G-Code is the drilling cycle, so let’s dive in and look at how we can use the G81 drilling cycle on a CNC mill. Using G81 G81 is the standard drilling cycle that produces our holes with just a few lines of code. In this article, we are going to dive into the world of drilling canned cycles and how we can program them using G-Code. Canned cycles are used when we are programming by hand to speed up the programming process. Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – .

cnc programming for dummies

When selecting tools, consider the type of work you will be doing, your budget, and reviews and recommendations from other metal fabricators. With the right tools and equipment, you can tackle any metal fabrication project with confidence and produce outstanding results.

cnc machine cycle program|cnc lathe programming for beginners