cnc machine var A basic look at programming G-Code with variables on a CNC lathe with an example program - Learn macro b programming with GCodeTutor. Arc welding leverages on the creation of an electric arc that melts the metals hence joining them together. The electric arc is created between the base metal and the consumable/non-consumable electrode. Electricity can either be .

0 · macro programming for cnc

1 · cnc system variables list

2 · cnc macro programming manual

3 · cnc g code variables

Dark Blue 2 piece box with the blue metal corners. With the Parts List, Instructions for Use, Maintence Manual with the warrentee card inside. 98% condition $30.00 Plus .

A basic look at programming G-Code with variables on a CNC lathe with an example program - Learn macro b programming with GCodeTutor.Vim Var is the double melting process combining vacuum induction melting (VIM) and vacuum arc remelting (VAR). This process is designed to give materials a low degree of nonmetallic .

Variables are the heart of macro programming. Variables are like numbered storage units, each of which can either be empty or contain a number. When they contain a number, the variables . There are five variable types in custom macro: • Letter address arguments are used in custom macro to call G65 or G66 commands. • Local variables range from #1 through . In most cases you have to buy through a VAR and he will be your first line of paid for support and you WILL have to pay them bad or good every year you stay current. Here is .A macro statement can assign a value to a variable, read a value from a variable, evaluate an expression, conditionally or unconditionally branch to another point within a program, or conditionally repeat some section of a program. Here are .

So far, we’ve learned how to parameterize g-code with variables and expressions and how to package it into building blocks using subprogram and macro calls, but these three simple concepts of GOTO, IF, and WHILE, will . I am having some trouble drilling in 304 L VAR. Background: using a Walter B4213 indexable insert drill (.656") in a Mori Sieki SL200 lathe, drilling 1.375" deep hole on center. . In CNC machining, a macro is a set of programmatic instructions most often used for automating repetitive tasks and saving on programming time. Macros in CNC programming can be used to store variables, perform .

Fanuc macro variable chart listing for macro programming. Macro variables for offsets, geometry, wear, tool compensation etc.VIM VAR The Best CNC Machined Components Made by Owens Industries. Vim Var is the double melting process combining vacuum induction melting (VIM) and vacuum arc remelting (VAR). This process is designed to give materials a low degree of nonmetallic inclusions and soft magnetic properties after they have been heat-treated. Today most CNC machines operate as milling machines, lathes, laser machine or even CNC grinders.   These machines work to quickly and  automatically engrave, route, or cut materials, including wood, plastics,  and . File Extension: Data in the File.VAR: Macro Variables, Probe and Calibration data.SET: Settings (except settings 900-911).OFS: Work Offsets, Tool Offsets

Gorilla CNC Machines; K2CNC; Larken; Multicam Machines; Omni CNC; Roctech CNC Routers; Shopsabre; Stepcraft; Techno CNC; XYZ Gantry Routers; DIY CNC Router Table Machines. FAQ of DIY CNC Machine Building; Avid CNC; CNC Wood Router Project Log; FineLine Automation; Joes CNC Model 2006; Momus Design CNC plans; Open Source CNC Machine Designs; Zen .We provide high precision machining of large, complexly shaped parts for hydro, oil & gas, marine and automotive industries. . CNC TVAR industry solutions For years we focus on the global power industry. Today`s demanding market seeks for flexibility, reliability and cost effective manufacturing solutions. .

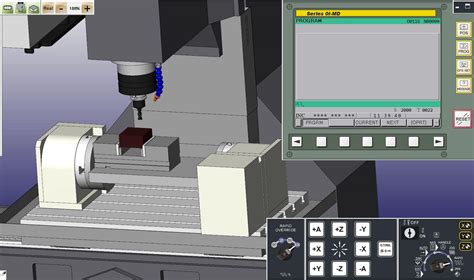

CNC Machine works with CAD/CAM software and G code for automated machining. The programming begins using CAD software to create a digital design. Then CAM translates the CAD-based design and generates the necessary parameters and instructions. For specific operations, CNC machines are equipped with different tools and accessories.The UMC-350HD-EDU is a specially priced education-edition machine that is perfect for schools as a first step into 5-axis CNC machining and training. It combines the 40-taper performance of our DM-1 Drill/Mill Center with the versatility of our TRT210 dual-axis rotary to create a small UMC that’s perfect for teaching the fundamentals of 3+2 .Control Overview. Let’s take a quick look at the FANUC control to get you up and running on your machine! The FANUC control can be tricky for new users, but thanks to some help from a few FANUC friends this should hopefully get you headed in the right direction making parts! Hi guys, I am having some trouble drilling in 304 L VAR. Background: using a Walter B4213 indexable insert drill (.656") in a Mori Sieki SL200 lathe, drilling 1.375" deep hole on center. Currently running 1100 RPM @ .0025 IPR per Walter app. Problem is the inserts deteriorate much much faster.

That is also why you need a larger breaker to handle the power up surge from the capacitive load when the machine is first turned on. Your machine should draw much less than an air conditioner unit. When I got my first CNC with a 2 HP spindle I was running it 8-10 hours a day and I barely noticed any change in my electric bill. Cnc Machine Kaise Kam Karte Hai.. The Brother Speedio M200X3 is their 2nd-gen multi-tasking 5-axis CNC mill capable of 3+2/4+1 machining and 2000rpm turning. The 3rd generation model, the Brother Speedio M200Xd1, was released in 2022 with a 28-slot ATC (up from 22) and a new controller (CNC-D00) that supports simultaneous 5-axis machining (5AX option).

cnc machine for 3d wood carving

The Best CNC Routers for Woodworking 1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers. Price: Starting at ,525 — Available at Matterhackers here Materials: Wood, Plastics, Soft Metals Work Area: 17.5″ x 17.5″ x 4″ Accuracy: 0.005″ Assembly Time: Around 4 hours

macro programming for cnc

CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is known for its high precision and versatility in creating a wide range of materials, including metal, plastic, wood, foam, and .

Hi, I'm running into trouble trying to setup a 5-axis post-process for the 5axismaker (5axismaker.com) to run on Mach3. I have successfully run this machine as a general 3-axis CNC with the Mach3, but I am lost on how to a) program the 5 axis tool paths in CAM in Fusion 360 and b) how to post process in the Mach3mill for the 5axismaker with 5 axes.I recently upgraded my CAM software from UCanCam V9.6 to Aspire V10.5 and the problem I'm facing right now is that the Aspire doesn't have the post processor for my CNC. The old CAM software's post processor file is in .set format which . A CNC machine tool always has a sliding table and a spindle to control the position and speed. The table of the machine is controlled in the X and Y-axis direction and the spindle is controlled in the Z-axis direction. Driving .

cnc machine florida

Our on-site instructor led programs are designed to provide an extensive learning experience without disruption to the facility. These programs can be customized to meet the needs of the participating facility and cover subjects including CNC controls, machine setup, work holding, tool section, multi-axis programming, automation, and probing. Higher laser power means faster cutting speeds and the ability to cut through thicker materials. Our CNC laser cutting machine for metal can cut stainless steel up to 7mm or 0.27” thick, carbon steel up to 16mm or 0.63” and aluminum sheet up to 6mm or 0.24”.Maybe 90% of what we have live tool paths on are pretty basic on our other machines. Usually a single operation. I can't remember what the quote was from the MasterCAM VAR was. maybe k-k (he may have included adding the mill plug-in for lathe, which we already have). Maybe I'll wait and see what our guy thinks with a little hands-on.THE LIMITLESS POSSIBILITIES OF A FLEXCNC MACHINING CENTER The FlexCNC is more than a standard machining center. With features that help businesses increase throughput and profit, it outperforms the competition with next-level productivity. FlexCNC machines are purpose-built for accuracy and efficiency. Our vertical machining centers are uniquely capable of .

*Haas machines are designed to operate on 220 VAC (200-240 VAC) power. An optional internal high-voltage transformer (380 - 480 VAC) is available for all models, except the Desktop Machines, CL-1, CM-1, and SR Series routers. This optional high-voltage internal transformer is not field installable; it must be ordered with the machine. ATTENTION!Haas VR Series VMCs are the perfect solutions when your 5-axis parts are too large to rotate using traditional rotary tables and trunnions. Each VR Series machine features a large T-slot table that easily supports large workpieces and fixtures, and a powerful 2-axis gimbaled spindle head that provides access to nearly any angle on the part for complex shapes, undercuts, and 5 .Our precision CNC machining company has been a veteran-owned, family-run business since 1975. In that time our company values have always been those of superb craftsmanship, innovative solutions and quality products. Our Team and FacilityThe Haas Bar Feeder is a simple and affordable way to automate part production on Haas turning centers to boost productivity. It is designed and built exclusively for use on Haas turning centers, and connects directly to the Haas control.

CNC Machining . Machining Kanthal, anyone have any experience with it? Thread starter laminar-flow; Start date May 12, 2020 . 304L VAR machining. Lunchbox1029; Aug 29, 2023; CNC Machining; Replies 11 Views 410. Aug 31, 2023. Lunchbox1029. L. G. New B-axis machine - experience Doosan SMX2100, Nakamura CTRX-300.¶Changes to configuration files. To configure RepRapFirmware for a CNC machine, follow the instructions for configuring RepRapFirmware for a 3D printer using the same architecture (e.g. Cartesian), ignoring anything to do with extruders. ¶ config.g changes RepRapFirmware has a default minimum movement speed of 0.5mm/sec, or 30mm/minute.

cnc system variables list

Our proven Square WaveTM technology provides the home hobbyist with a smooth and stable AC TIG welding on aluminum from a machine that also provides for great DC TIG welding on steel .

cnc machine var|macro programming for cnc