cutting 18 gauge sheet metal Learn how to cut sheet metal with our step-by-step guide showing multiple techniques for precise, safe cuts for your DIY projects. When cutting sheet metal, it’s crucial to . Industrial Enclosures, Sheet Metal Fabrication, & Custom Kiosks. Gamlet's has innovative products, competitive costs, and superior service.

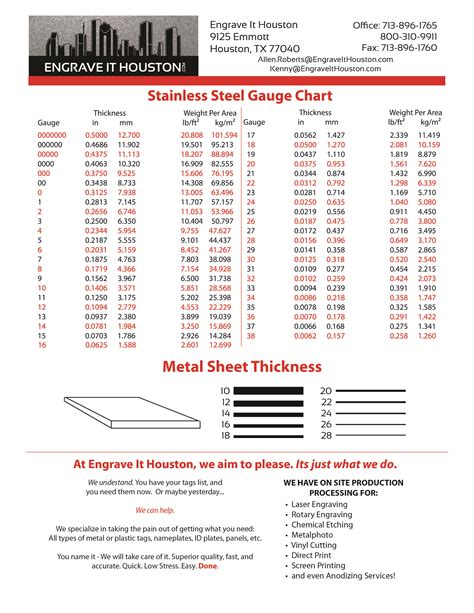

0 · sheet metal gauge chart

1 · metal plate gauge thickness chart

2 · 18ga sheet metal near me

3 · 18 gauge to fraction

4 · 18 gauge sheet metal thickness

5 · 18 gauge sheet metal near me

6 · 18 gauge galvanized steel sheet

7 · 18 gauge galvanized sheet metal

Wholesale Sheet Metal. Raw material: Stainless Steel, Aluminum, Copper, Brass, Iron, Galvanized, Carbon Steel SPCC, SPHCC SGCC,SECC.etc. Dimension: As Per Your .

One of the fastest, most precise sheet metal cutting methods is to cut with a high-power laser. There are modern laser machines available that can cut and format automatically . Today I’ll go over three different tools you can use to cut sheet metal and plate. Learn how to cut sheet metal with our step-by-step guide showing multiple techniques for precise, safe cuts for your DIY projects. When cutting sheet metal, it’s crucial to . A circular saw is ideal for cutting all gauges of sheet metal, even the thickest of sheets, and it is ideal for cutting straight lines. If you have pieces that need to be separated into various sections, then this is one of the best .

Designed to cut 18-gauge cold-rolled or 23-gauge stainless steel. Color-coded aviation snips are helpful. They come with red, yellow, and green handles, or a strip of each of these colors on the handles, and sometimes there are white . There’s nothing wrong with using a good, old-fashioned hacksaw, but there are faster, easier ways to cut metal. We’ll show you power tool tips and techniques for cutting the types and thicknesses of metal that DIYers handle .

Standard sheet metal is thin, galvanized steel. It's the same material ducts are made of and is commonly sold in large, flat sheets in 18- to 28-gauge thicknesses. You can also find sheet metal in aluminum or even copper and . There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is.

opalescent metal casket box

Also referred to as aviator snips, these scissor-like hand tools cut sheet metal materials up to 18-gauge in thickness accurately without leaving a ragged, bent edge as the finished. One of the fastest, most precise sheet metal cutting methods is to cut with a high-power laser. There are modern laser machines available that can cut and format automatically once you set the track. The speed and orientation of cutting with laser tools are limited within 2D. Today I’ll go over three different tools you can use to cut sheet metal and plate. Learn how to cut sheet metal with our step-by-step guide showing multiple techniques for precise, safe cuts for your DIY projects. When cutting sheet metal, it’s crucial to use the correct methods to get the best results while staying safe.

A circular saw is ideal for cutting all gauges of sheet metal, even the thickest of sheets, and it is ideal for cutting straight lines. If you have pieces that need to be separated into various sections, then this is one of the best methods that you have at your disposal.Designed to cut 18-gauge cold-rolled or 23-gauge stainless steel. Color-coded aviation snips are helpful. They come with red, yellow, and green handles, or a strip of each of these colors on the handles, and sometimes there are white snips too. It’s important to understand what the colors mean and to use the right one for the right job. There’s nothing wrong with using a good, old-fashioned hacksaw, but there are faster, easier ways to cut metal. We’ll show you power tool tips and techniques for cutting the types and thicknesses of metal that DIYers handle the most. Standard sheet metal is thin, galvanized steel. It's the same material ducts are made of and is commonly sold in large, flat sheets in 18- to 28-gauge thicknesses. You can also find sheet metal in aluminum or even copper and brass, and they all can be cut using the same tools and techniques.

Aviation snips and tin snips are a common method of cutting thin sheet metal for hobbyists. These tools are good for cutting soft sheet metals such as tin, aluminum and brass. You probably wont find snips which are capable of cutting above 18 gauge mild steel. For a reference on gauge thickness see our gauge chart.

There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is.

Also referred to as aviator snips, these scissor-like hand tools cut sheet metal materials up to 18-gauge in thickness accurately without leaving a ragged, bent edge as the finished. One of the fastest, most precise sheet metal cutting methods is to cut with a high-power laser. There are modern laser machines available that can cut and format automatically once you set the track. The speed and orientation of cutting with laser tools are limited within 2D. Today I’ll go over three different tools you can use to cut sheet metal and plate. Learn how to cut sheet metal with our step-by-step guide showing multiple techniques for precise, safe cuts for your DIY projects. When cutting sheet metal, it’s crucial to use the correct methods to get the best results while staying safe.

A circular saw is ideal for cutting all gauges of sheet metal, even the thickest of sheets, and it is ideal for cutting straight lines. If you have pieces that need to be separated into various sections, then this is one of the best methods that you have at your disposal.

Designed to cut 18-gauge cold-rolled or 23-gauge stainless steel. Color-coded aviation snips are helpful. They come with red, yellow, and green handles, or a strip of each of these colors on the handles, and sometimes there are white snips too. It’s important to understand what the colors mean and to use the right one for the right job. There’s nothing wrong with using a good, old-fashioned hacksaw, but there are faster, easier ways to cut metal. We’ll show you power tool tips and techniques for cutting the types and thicknesses of metal that DIYers handle the most. Standard sheet metal is thin, galvanized steel. It's the same material ducts are made of and is commonly sold in large, flat sheets in 18- to 28-gauge thicknesses. You can also find sheet metal in aluminum or even copper and brass, and they all can be cut using the same tools and techniques.

sheet metal gauge chart

Wenzel leads the metal spinning industry by producing custom concentric and symmetrical metal parts in production quantities. This process can be performed by manually by hand or by a CNC lathe, and is a cost-effective alternative to low volume or short run metal stamping.

cutting 18 gauge sheet metal|sheet metal gauge chart