advantages of cnc cutting machine CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique . What is Sheet Metal Processing? "Sheet metal" in sheet metal processing refers to thin metal plates, which can be processed by stretching, stamping, bending, etc., and the thickness is usually less than 6mm.

0 · disadvantages of cnc milling

1 · disadvantages of cnc machines

2 · cnc milling advantages and disadvantages

3 · cnc machining advantages and disadvantages

4 · cnc machine pros and cons

5 · advantages of cnc milling machine

6 · advantages and disadvantages of cnc

7 · advantages and disadvantages milling process

A sheet metal worker specializes in working with thin metal sheets to fabricate, install, and maintain various products and systems. They use blueprints and technical drawings to measure, cut, shape, and join metal sheets using methods like welding, soldering, or riveting.

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique .CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and .1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions. The CNC unit is responsible for the .

What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process . One of the most significant advantages of CNC machining is its high precision and consistency. Unlike traditional machining methods, which rely heavily on manual operation, . CNC (Computer Numerical Control) machining offers high precision, consistency, and efficiency, making it ideal for producing complex parts in industries like aerospace, . Some of the key advantages of CNC milling include: The precision and consistency of it machines contribute significantly to enhancing your efficiency and productivity. With reduced errors and faster task completion of .

What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and product developers alike. From aerospace components to custom automotive parts, this innovative process ensures high-quality output and cost-effectiveness.1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting.

CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb. Modern-day CNC machines are highly capable to the extent that they can even change their tools automatically! CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions. The CNC unit is responsible for the operation and monitoring of CNC machine tools and serves as its brain.

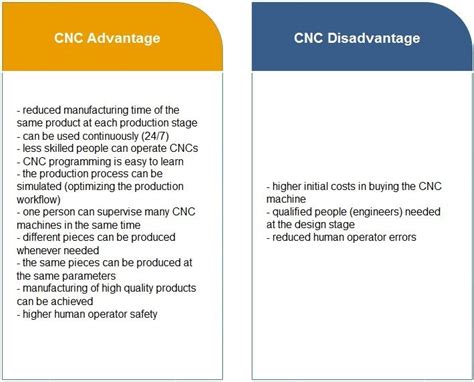

What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process Increases safety during machining Helps complete tasks faster and in details Reduces changeover time Boosts production volume One of the most significant advantages of CNC machining is its high precision and consistency. Unlike traditional machining methods, which rely heavily on manual operation, CNC machining utilizes computer-controlled systems to dictate the movements of machine tools. CNC (Computer Numerical Control) machining offers high precision, consistency, and efficiency, making it ideal for producing complex parts in industries like aerospace, automotive, and medical devices. Its key advantages include the ability to operate 24/7, reduced labor costs, and the capability to create intricate geometries. Some of the key advantages of CNC milling include: The precision and consistency of it machines contribute significantly to enhancing your efficiency and productivity. With reduced errors and faster task completion of cnc milling operations, .

What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and product developers alike. From aerospace components to custom automotive parts, this innovative process ensures high-quality output and cost-effectiveness.

1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb. Modern-day CNC machines are highly capable to the extent that they can even change their tools automatically! CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions. The CNC unit is responsible for the operation and monitoring of CNC machine tools and serves as its brain.

What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process Increases safety during machining Helps complete tasks faster and in details Reduces changeover time Boosts production volume One of the most significant advantages of CNC machining is its high precision and consistency. Unlike traditional machining methods, which rely heavily on manual operation, CNC machining utilizes computer-controlled systems to dictate the movements of machine tools. CNC (Computer Numerical Control) machining offers high precision, consistency, and efficiency, making it ideal for producing complex parts in industries like aerospace, automotive, and medical devices. Its key advantages include the ability to operate 24/7, reduced labor costs, and the capability to create intricate geometries.

sheet metal garden box

disadvantages of cnc milling

disadvantages of cnc machines

cnc milling advantages and disadvantages

How Pallet Changers Work in CNC Machine Tools A pallet is a movable & interchangeable part of a machine tool which helps to transport raw or finished parts from the machine in order reduce downtime for part loading/unloading. There are three main types of pallet changers in most CNC machine tools – manual, automated and robotic.

advantages of cnc cutting machine|advantages and disadvantages milling process