sheet metal forming processes manufacturer Cadrex is the foremost sheet metal manufacturer in North America, offering custom sheet metal fabrication services at strategically located facilities in the United States and Mexico. We provide our customers with the speed to scale . $46.99

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

Our skilled team of metal fabricators is dedicated to providing you with precision and expertise, ensuring that every project is executed to perfection. From custom metal designs to structural fabrication, we bring your ideas to life with attention to detail and a commitment to excellence.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .We provide fluid-cell solutions for sheet metal forming and pressing, used by major manufacturers worldwide. Global Leader in High Pressure Technology.FluidForming is a cost-effective sheet metal forming process designed for rapid prototyping & low- to medium-volume production. 800-497-3545.The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .

Cadrex is the foremost sheet metal manufacturer in North America, offering custom sheet metal fabrication services at strategically located facilities in the United States and Mexico. We provide our customers with the speed to scale . What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products .

By understanding the various processes, materials, and equipment involved in sheet metal forming, manufacturers can optimize their operations to meet the demands of diverse industries, producing high-quality components .If you are looking for sheet metal forming for your manufacturing needs in the areas of telecommunications, retail store fixtures, computers, electronic data racks and enclosures, industrial products, medical devices, and commercial .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.At Prince Manufacturing, we are experts in sheet metal forming and fabrication. Metal stamping and precision metal forming. Compared to casting and forging, sheet-metal parts offer the .In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling. Each process brings something unique to the .

Sheet Metal Bending & Forming Services. Whether you need simple bends, complex geometries, or custom shapes, our experienced team is well-equipped to handle any project, big or small. . Sheet metal bending is a manufacturing process in which a flat sheet of metal is formed into a desired shape by applying force to bend it along a straight axis. BENDING Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other .Explore the intricate process of sheet metal forming, its applications in various industries, and the distinction between sheet and plate metal. Learn about the manufacturing processes, the challenges with plate metal, and the final shaping of parts. . like deep drawing, there is a slight and expected change in thickness, but this may also be .

Although the advantages of formability are notable, blow-forming processes, which are classified as sheet metal stretching processes, present limits in terms of uniformity of the thicknesses of the produced product. Metal forming is a process of manufacturing components of desired shapes by deforming the material plastically, by the application of compressive force, bending or shear force, tensile force, or combinations of these all forces together, without adding or removing material. . Stretch forming is a sheet metal forming process in which the sheet .

Sheet metal forming is highly prevalent in manufacturing. Sheet metal parts can be discovered in a broad spectrum of applications, such as in the automotive sector, aerospace field, consumer goods, and household appliances. . Hydroforming is a specialized sheet metal forming process that utilizes high-pressure hydraulic fluid to shape the .

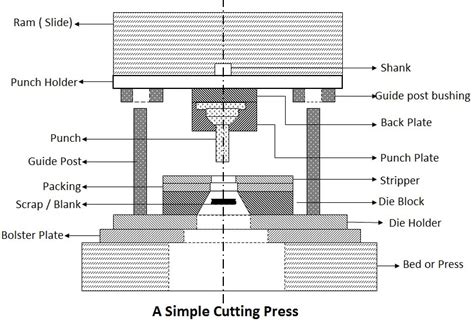

Sheet Metal Forming 2.810 D. Cooper . describe different forming processes, when they might . Small flexforming tool made by additive manufacturing . Stretch forming – very cheap tooling, net thinning, slow, low formability, sheet metal up to 15mx9m Loading Pre-stretchingSheet metal stamping is a cold-forming process using presses and dies to shape materials. It works with various metals, including stainless steel, carbon steel, aluminum, brass, and copper. Stamping combines cutting and forming techniques like bending, punching, embossing, and flanging to produce complex components quickly.Metal forming processes Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, punch etc. depending on the type of process. Plastic deformation: Stresses beyond yield strength of the workpiece material is required.

sheet metal working process pdf

The sheet-metal-forming process is crucial in manufacturing various products, including pipes, cans, and containers. . The procedure for designing the manufacturing process and the forming tool presented in the paper can be applied in cases where it is necessary to design a suitable technology to produce a small number of parts by forming to .

Consistency and Reproducibility: Metal forming processes are highly controllable, which ensures consistent quality and repeatability in mass production settings. Disadvantages of Metal Forming. High Initial Costs: The tooling and setup required for many metal forming processes, such as stamping and extrusion, can be costly. These initial .2. Deformation . Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical forming processes, and it can be done using a brake machine.A sheet metal company can use this tool to bend sheet metal into V, U, and channels up to 120 degrees. In sheet metal forming processes there is still a lack of knowledge in this field mainly due to the need of a proper modelling of sustainability issues and factors to be taken into account. . Calculation of carbon emissions in metal forming manufacturing processes with eco-bening lubrication. Trans. Namri/Sme, 38 (2010), pp. 751-758. View in .

Principles of Incremental Sheet Forming Incremental Sheet Forming is a versatile manufacturing process that involves the gradual deformation of a metal sheet using a localized tool. Unlike traditional forming processes that utilize dies and .

Processes – CNC Punching & Forming [email protected] 2024-06-17T20:57:48+08:00. Metal Punching & Stamping Services. . Sheet metal punching is a manufacturing process that involves using a punch and die set .The common materials used in manufacturing sheet metal are aluminum and stainless steel. The most known grades available in stainless steel are 304, 316 and 410. 304 is one of the most common grades. . Sheet Metal Forming Processes. This is a commonly used manufacturing process that helps in manufacturing the parts for tons of known and .Outsource your sheet metal forming and fabrication to Prince Manufacturing, we are experts in Metal stamping, and precision metal forming. . We reduced AM General’s manufacturing process from taking 5 days to 1 day. Fasco Motor Division process was reduced by 89% in length. From 10-14 days we reduced it to 1.5 days.Research and development in sheet metal shaping requires knowledge within several disciplines, including materials, tribology and processing, as well as knowledge of the equipment for testing and verification. Swerim has depth knowledge in the field and good access to lab equipment. Process, methods and materials for sheet metal forming

Stamping is a manufacturing process that involves pressing or forming sheet metal or other materials using a die and a press. This technique is used to create a wide range of components, from small intricate parts to large panels, in industries like automotive, electronics, and appliance manufacturing, due to its efficiency and precision.Typical Sheet Metal Working: Drawing Operation: (a) It is a forming process by pushing a punch against a flat sheet and forcing it into a die to take the required shape. Or in other words drawing is the operation of producing thin walled, hollow shaped parts from sheet metal. Both the die and the punch have shape of the part to be manufactured .

Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet metal parts. Because manufacturers typically perform these operations on presses with a set of dies, the terms pressworking or press .

Types of Sheet Metal Forming Processes Bending: Creating Angles, Curves, and Complex Geometries. Bending is a common sheet metal forming process that shapes the metal sheet along a straight axis to create angles, curves, and complex geometries. This process is widely used in manufacturing brackets, enclosures, frames, and other structural . By comparing the process chain of PBF-LB and forming (Fig. 2) with the process chain of subsequent sheet bulk metal forming operations (Fig. 5) it can be seen that, the main difference is the process step for manufacturing the tooth geometry on the sheet metal. In case of the hybrid approach, the tooth geometries are manufactured by PBF-LB on a .

sheet metal stamping process pdf

FluidForming is a cost-effective sheet metal forming process designed for rapid prototyping & low- to medium-volume production. 800-497-3545. . FluidForming Americas is a quality-driven sheet metal forming company that offers manufacturers a cost-effective way to quickly — and with unbeatable levels of accuracy and repeatability — produce .

Although the advantages of formability are notable, blow-forming processes, which are classified as sheet metal stretching processes, present limits in terms of uniformity of the thicknesses of the produced product.

What changed from old water heater installs is most water heaters now require a 30 amp breaker with #10 gauge wire (NEC improvement). At one time 20 amp with 12 gauge wire was the norm. Any modified work a licensed and insured electrician must do is bring the work to the latest code for your safety.

sheet metal forming processes manufacturer|sheet metal forming press dies