sheet metal welding standards Access free downloads of essential AWS welding standards and resources. Explore a wide range of welding guidelines and documents to support your welding projects and safety practices. Have you ever noticed a star adorning the exterior of a house and wondered about its significance? These stars are seldom the same, often seen in various colors, sizes, and materials — they are not just decorative elements; they carry a wealth of history and meaning.

0 · welding standards pdf

1 · welding standards australia

2 · welding standards and regulations

3 · welding specifications standards and codes

4 · welding specification pdf

5 · standard welding procedures pdf

6 · list of aws welding standards

7 · aws welding symbols chart pdf

When it comes to screw size for a metal electrical box, several factors come into play, including the type of application and the weight it needs to support. The most common screw size for metal electrical boxes is #6-32, which is suitable for standard outlets and switches.

This code covers the arc and braze welding requirements for nonstructural sheet metal fabrications using the commonly welded metals available in sheet form. Requirements and limitations governing procedure and performance .

It provides qualification, workmanship, and inspection guidelines that apply to the fabrication, manufacture, and erection of nonstructural sheet .The 2000 edition, D9.1M/D9.1:2000, Sheet Metal Welding Code, provides for maintenance of the document and updates to keep abreast of practices being encountered in sheet metal welding .Welcome to the AWS Welding Standards page, where you'll find a comprehensive resource for welding standards and guidelines. Discover how AWS standards contribute to the .

Access free downloads of essential AWS welding standards and resources. Explore a wide range of welding guidelines and documents to support your welding projects and safety practices.

View More. This code covers the arc and braze welding requirements for nonstructural sheet metal fabrications using the commonly welded metals available in sheet .AWS D9.1/D9.1M:2018. Sheet Metal Welding Code. This code covers the arc and braze welding requirements for nonstructural sheet metal fabrications using the commonly welded metals .This document is part of a series of standards dealing with specification and qualification of welding procedures. Annex A gives details of this series of standards, Annex B gives a table .

Learn about the American Welding Society's (AWS) Standard Welding Procedure Specifications (SWPS). Explore guidelines, procedures, and best practices for achieving welding excellence .Welcome to the AWS Welding Standards page, where you'll find a comprehensive resource for welding standards and guidelines. . The award-winning Welding Journal has been the leading authority in metal fabrication for more than 100 years. Each month, the magazine explores the latest welding products, trends, and technology — and it’s free .

Other than the extrusion of the materials, sheet metals are crafted into product design largely through welding processes. AWS D9.1/D9.1M:2018 – Sheet Metal Welding Code offers guidelines for sheet metal welding to keep .

This code provides qualification, workmanship, and inspection requirements for both arc welding (Part A) and braze welding (Part B), as they apply to the fabrication, manufacture, and erection of nonstructural sheet metal components and systems. 1.1.1 This code was developed to provide standardized requirements for the qualification, production . 1) sheet metal tolerance Standards 2) Welding Tolerance standards 3) General Tolerance Standards 4) V groove Pulley Standard DImensions if required in deep or for any queries pls mail us to [email protected]. DeleteIn the case of thinner sheet metal or highly ductile metals (such as aluminum or copper), even more care must be taken in the sheet welding process. How to weld thin sheet metal. Heat is essential when welding thinner material. Minifaber machines can control the amount of heat, welding any sheet below 0.8 mm without any problem. With this type . AW S D09.1 Sheet metal welding. AW S D10.10 Heating practices for pipe and tube. . NA 092 is the Standards Committee for welding and allied processes (NAS) at DIN Deutsches Institut für .

Manufacturers often have to fit several parts to make a whole during fabrication. Sheet metal welding is a crucial manufacturing process that helps join and assemble metal structures. However, it’s a relatively complex process that requires technical skill to ensure your fabrication meets industrial standards. This article introduces you to welding sheet metal, .

welding standards pdf

Welding standards and codes are special procedures followed during welding processes. The codes vary from metal to metal depending on their base materials. . Sheet Metal Welding. AWS D10.10. Heating Practices for Pipe and Tube. AWS D10.11. Root Pass Welding for Pipe. AWS D10.12. Pipe Welding (Mild Steel) AWS D10.13.

Part C: Specifications for Welding Rods, Electrodes and Filler Metals. [a] ASME BPVC Section III . Sheet metal welding AWS D10.10: Heating practices for pipe and tube AWS D10.11: Root pass welding for pipe AWS D10.12: Pipe welding (mild steel) AWS D10.13: Tube brazing (copper) SMACNA standards and manuals address all facets of the sheet metal and HVAC industry—including duct construction and installation, indoor air quality, energy recovery, roofing and architectural sheet metal, welding, and commissioning— and advancements are made possible by those in the industry who provide suggestions for improvement based . 8.1 Considerations for TIG welding; 9 Sheet Metal Part Design for Manufacturing Tip. 9.1 CORNERS AND WELDING; 10 Sheet Metal Fabrication Welding FAQ. 10.0.1 What are the key welding methods used by fabricators? 10.0.2 What is the difference between spot welding and tack welding? 10.0.3 When should fuse welding be used, and what materials are .

awsd91m2012-Sheet Metal Welding Code-This code provides qualification, workmanship, and inspection requirements for both arc welding (Part A) and braze welding . HOME; . Standards Subscriptions from ANSI provides a money-saving, multi-user solution for accessing standards.

AWS QC17:2015, Standard for Accreditation of Welding Fabricators for AWS Certified Welding Fabricator Program . AWS D9.1/D9.1M:2018 Sheet Metal Welding Code - Annex D, E, and F (Informative) DOWNLOAD . AWS D10.10/D10.10M:2021 Recommended Practices for Local Heating of Welds in Piping and Tubing - Annex G (Informative)Tolerances are critical in the joining stage of many sheet metal projects. Welding: Tolerances in welding are affected by factors like the welder’s skill, the type of welding used (MIG or TIG), etc. The materials being joined and the welder’s skill are important factors. . ISO Standards: The International Organization for Standardization . GENERAL WELDING STANDARDS (GWS) - Provides the administrative controls for development and implementation of the LANL Welding Program. . 2-06, AWS D1.3/9.1 Sheet Metal Welding : 1: 10/27/06 : 2-07, AWS D1.6, Structural Stainless Steel : 1: 10/27/06 : 2-08, AWS Stud Welding (In Development) -- 2-09, DOE Nuclear Applications : 1: 10/27/06 Att.1 .The 2000 edition, D9.1M/D9.1:2000, Sheet Metal Welding Code, provides for maintenance of the document and updates to keep abreast of practices being encountered in sheet metal welding and joining processes since the last revision. The 2006 edition D9.1M/D9.1:2006, Sheet Metal Welding Code, also provides for maintena nce of the document and pre-

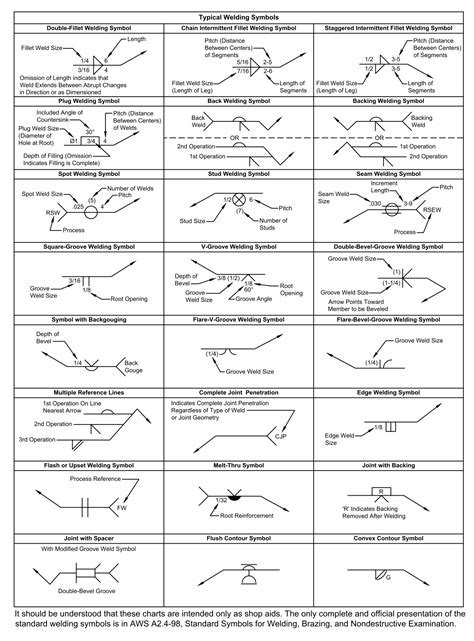

Sheet metal welding is a crucial fabrication process because it is one of the simplest ways to join cut-out pieces of metal sheets to create the desired shape. . There are two standard machines for laser welding . Welding Materials: Refer to SMACNA – Sheet Metal Welding Guide. 2.2 DUCTWORK MATERIALS A. Flexible Duct: 1. Shall be factory fabricated, listed and labeled as a UL 181 Class 1 air duct, and shall comply with NFPA 90A and NFPA 90B. . HVAC Duct Construction Standards – Metal and Flexible for sheet and joint deflection at the required . Therefore, there must be sheet metal welding standards regarding information representation on your welding drawings that should relays same message irrespective of person reading. welding symbols for sheet metal. Therefore, the standard 8 .

AWS D9.1M/D9.1:2000 An American National Standard Sheet Metal Welding Code Key Words—Sheet metal, arc welding, braze welding, AWS D9.1M/D9.1:2000 joint designs, qualification, workmanship, An American National Standard inspection, base metals, filler metals Approved by American National Standards Institute August 3, 2000 Sheet Metal Welding Code .standard by the American Welding Society does not carry with it any right to make, use. or sell any patented items. Users of the information in this standard should make an independent, subsiantiating investigation of the validity of that . Sheet Metal Welding Code Supplement C to AWS QC7-93 specifies requirementsThis section highlights OSHA standards and documents related to welding, cutting, and brazing. OSHA Standards. General Industry (29 CFR 1910) General Industry (29 CFR 1910) Related Information; . Welding, cutting and heating of hollow metal containers and structures not covered by § 1915.12. Related Information: 1915.55, Gas welding and cutting. Japanese Industrial Standards (JIS) are used to define the specifications and testing methods for metal materials in Japan. JIS standards emphasize high precision and quality, making them particularly relevant for industries that demand the highest manufacturing standards, such as electronics and automotive production.

AS NZS 1554.1 2014 specifies requirements for the welding of steel structures made up of combinations of steel plate, sheet or sections, including hollow sections and built-up sections, or castings and forgings. . 4.7.8 Hardness comparison test for parent metal and weld metal. 4.7.9 Hardness test for weld-heat-affected zones. 4.7.10 Retests.The 2000 edition, D9.1M/D9.1:2000, Sheet Metal Welding Code, provides for maintenance of the document and updates to keep abreast of practices being encountered in sheet metal welding and joining processes since the last revision. The 2006 edition D9.1M/D9.1:2006, Sheet Metal Welding Code, also provides for maintena nce of the document and pre- Explore expert sheet metal welding services, offering precision, durability, and custom solutions for all your industrial and commercial needs. . Deliver precision automotive parts that surpass industry standards. Our manufacturing ensures exceptional quality, reliability, and performance for your vehicles. .Permission to reproduce for intra-company use only is granted by the American Welding Society Standard Welding Procedure Specification (SWPS) Shielded Metal Arc Welding of Carbon Steel (M-1/P-1, Group 1 or 2), 1/8 inch [3 mm] through 1-1/2 inch [38 mm] Thick, E7018, in the As-Welded or PWHT Condition, Primarily Plate and Structural Applications

welding standards australia

In this article, we will discuss the best welders for sheet metal. We will provide product reviews and useful tips to help you choose the right welder for your needs! What welder is best for thin sheet metal? Can you weld sheet metal with a MIG welder? How thick of metal can a MIG welder weld? Is MIG stronger than stick welding?

sheet metal welding standards|welding standards and regulations