bending box section steel Bending and roll bending of metal tubes, box section tube and profiles are activities which traditionally fall into the metallurgy industry. This regards processing of metals which . Metallic Smell. As with the scent of sulfur, a metallic smell likely means that something is malfunctioning within the air conditioning unit or furnace. It could be the evaporator coil or another part of the system that you cannot access on your own. If this is the case, shut down the system and call in a repair service immediately. Chemical Smell

0 · tube bending design

1 · steel tube bending

2 · how to bend box section

3 · how to bend a box

4 · box section metal bending

5 · box section bending radius

6 · box section bending

7 · bending of metal tubes

Looking to get a serious jump-start on your quest for self preservation? This level includes everything from the Survivor, with the addition of higher value products that are there when you need them most.In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .

Bending and roll bending of metal tubes, box section tube and profiles are activities which traditionally fall into the metallurgy industry. This regards processing of metals which .The bending radius that can be achieved for a steel tube with the application of tube .With this machine we bend circular hollow sections ranging from a minimum .

metallic silver quilted fabric

Roll bending is a process of cold deformation of metal tubes, which . What is the best way to bend box section? I am looking to be able to bend 40mm box, wall thickness of 3mm to a diameter of 1200mm. Hopefully it is possible to do without .

square or rectangular (box) section is possible and even oval shapes or more complex sections can be bent. Rigid tube offers a more robust, longer life, often lower total cost solution . Bending metal tubing is easier than you might think. the first thing you need is a fixture. the design of the fixture is determined by the material being bent and the quantity of tubes.With over 25 section bending machines in operation, our large capacities mean we can turn around customer jobs quickly and economically, regardless of size, intricacy, or volume. Download our Section bending brochure here

Table of design properties for steel square profiles / square hollow sections (SHS) according to Eurocode 3 including cross-section dimensions & design resistance. Calculate your stresses and moments here (filling in the . Here's some tips on cutting, welding and finishing steel box corners to a seamless finish.

Barnshaws have a wide range of machinery for bending aluminium and non-ferrous sections, extrusions and sheet metal. We specialise in bending various bespoke architectonical and automotive sections with very complex shapes . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. Bending and roll bending of metal tubes, box section tube and profiles are activities which traditionally fall into the metallurgy industry. This regards processing of metals which deals with their deformation by means of bending and roll bending techniques. What is the best way to bend box section? I am looking to be able to bend 40mm box, wall thickness of 3mm to a diameter of 1200mm. Hopefully it is possible to do without heating it up.

square or rectangular (box) section is possible and even oval shapes or more complex sections can be bent. Rigid tube offers a more robust, longer life, often lower total cost solution compared to flexible hose and is visually more appealing. Complex bend paths or hose/tube combinations can eliminate multiple components and leak paths. We discuss some of the similarities and differences between bending square tubing, rectangular, and round tube. Learn how to bend square tubing here.

Bending metal tubing is easier than you might think. the first thing you need is a fixture. the design of the fixture is determined by the material being bent and the quantity of tubes.

With over 25 section bending machines in operation, our large capacities mean we can turn around customer jobs quickly and economically, regardless of size, intricacy, or volume. Download our Section bending brochure here Table of design properties for steel square profiles / square hollow sections (SHS) according to Eurocode 3 including cross-section dimensions & design resistance. Calculate your stresses and moments here (filling in the appropriate area and moment of inertia data from above). The most powerful online free beam calculator. Here's some tips on cutting, welding and finishing steel box corners to a seamless finish.

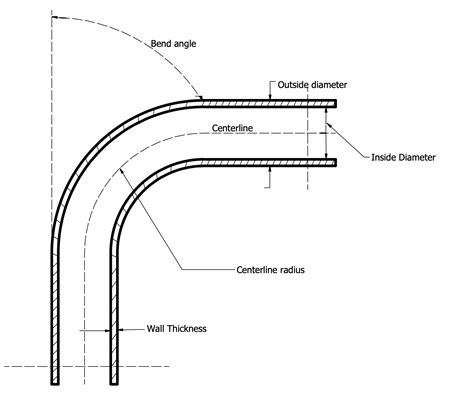

Barnshaws have a wide range of machinery for bending aluminium and non-ferrous sections, extrusions and sheet metal. We specialise in bending various bespoke architectonical and automotive sections with very complex shapes based on our Customers requirement. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. Bending and roll bending of metal tubes, box section tube and profiles are activities which traditionally fall into the metallurgy industry. This regards processing of metals which deals with their deformation by means of bending and roll bending techniques.

What is the best way to bend box section? I am looking to be able to bend 40mm box, wall thickness of 3mm to a diameter of 1200mm. Hopefully it is possible to do without heating it up.square or rectangular (box) section is possible and even oval shapes or more complex sections can be bent. Rigid tube offers a more robust, longer life, often lower total cost solution compared to flexible hose and is visually more appealing. Complex bend paths or hose/tube combinations can eliminate multiple components and leak paths. We discuss some of the similarities and differences between bending square tubing, rectangular, and round tube. Learn how to bend square tubing here.

Bending metal tubing is easier than you might think. the first thing you need is a fixture. the design of the fixture is determined by the material being bent and the quantity of tubes.

With over 25 section bending machines in operation, our large capacities mean we can turn around customer jobs quickly and economically, regardless of size, intricacy, or volume. Download our Section bending brochure here Table of design properties for steel square profiles / square hollow sections (SHS) according to Eurocode 3 including cross-section dimensions & design resistance. Calculate your stresses and moments here (filling in the appropriate area and moment of inertia data from above). The most powerful online free beam calculator.

Here's some tips on cutting, welding and finishing steel box corners to a seamless finish.Barnshaws have a wide range of machinery for bending aluminium and non-ferrous sections, extrusions and sheet metal. We specialise in bending various bespoke architectonical and automotive sections with very complex shapes based on our Customers requirement.

tube bending design

Fortunately, stainless steel finishes are team players in a kitchen’s design and work beautifully with many color palettes. Here, we’re highlighting several kitchen color schemes that.

bending box section steel|how to bend a box