electrical box knockout osha Response: Yes, §1910.147 (a) (1) (ii) (D) requires the lockout or tagout of electrical hazards for work on, near, or with conductors or equipment in electric-utilization installations, .

Get instant online quote for your metal or plastic CNC machined parts, from rapid prototyping to production. Choose from 100+ materials, 60+ surface finishes. ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified. Experience lead times as short as 1 day.

0 · open knockouts on outlet boxes

1 · open knockouts in electrical panels

2 · knockout sizes for electrical boxes

3 · knockout plugs for electrical outlet

4 · knockout plugs for electrical boxes

5 · electrical knockout hole size chart

6 · electrical box knockout sizes chart

7 · electrical box knockout reducing washers

Discover our extensive range of affordable aftermarket CNC replacement parts, designed to keep your machines operating at peak performance. Our high-quality 100% Free Shipping in USA!

All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.Response: Yes, §1910.147 (a) (1) (ii) (D) requires the lockout or tagout of .Electrical standard requirements concerning covers for electrical pull boxes, junction .

sentinel steel security cabinet key

Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following .The photograph on the right is a knockout in a standard outlet box, that has been pushed in. The hazard with that is if an employee comes up to that, and is plugging something in, and their finger inadvertently goes into that hole that .

Response: Yes, §1910.147 (a) (1) (ii) (D) requires the lockout or tagout of electrical hazards for work on, near, or with conductors or equipment in electric-utilization installations, .You may notice a broken, loose, or missing cover on an electrical receptacle or junction box. Or perhaps it’s a missing “knockout” plug on the side of an electrical box. Or, you may . Since exposure to electricity could cause serious physical harm, OSHA can cite that paragraph for a number of hazards. A search for citations finds things like damaged insulation on wiring, or exposed electrical parts of .

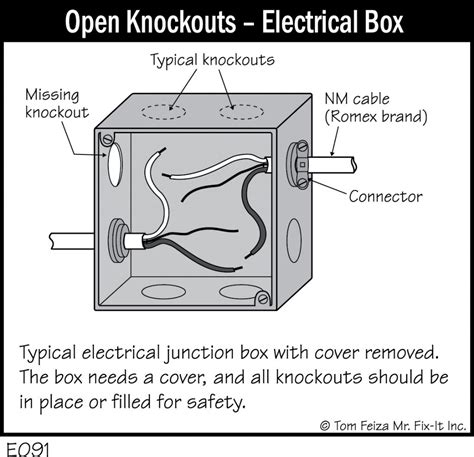

Many times the opening is an open knockout where a used box is installed and the opening is not properly plugged. The primary issue with covers and canopies is that junction and pull boxes are often left uncovered. Knockouts are perforated circles cut into the sides, top, bottom, and back of an electric panel box that can be “knocked out” for the entry of wiring in conduit or NM-cable.

Electrical standard requirements concerning covers for electrical pull boxes, junction boxes, and fittings. OSHA requirements are set by statute, standards and regulations. Our . Here's how to remove a knockout in order to run wires through the electrical box. Knockouts are partially stamped, quarter-size openings in the electrical boxes.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;

The photograph on the right is a knockout in a standard outlet box, that has been pushed in. The hazard with that is if an employee comes up to that, and is plugging something in, and their finger inadvertently goes into that hole that has been knocked out, they can make contact with live electrical parts inside that housing, so that's . Response: Yes, §1910.147 (a) (1) (ii) (D) requires the lockout or tagout of electrical hazards for work on, near, or with conductors or equipment in electric-utilization installations, be done in accordance with §1910, Subpart S.

You may notice a broken, loose, or missing cover on an electrical receptacle or junction box. Or perhaps it’s a missing “knockout” plug on the side of an electrical box. Or, you may occasionally come across an open hole in the face of an electrical breaker panel where one or more electrical breakers are missing.

Since exposure to electricity could cause serious physical harm, OSHA can cite that paragraph for a number of hazards. A search for citations finds things like damaged insulation on wiring, or exposed electrical parts of equipment motors.Many times the opening is an open knockout where a used box is installed and the opening is not properly plugged. The primary issue with covers and canopies is that junction and pull boxes are often left uncovered. Knockouts are perforated circles cut into the sides, top, bottom, and back of an electric panel box that can be “knocked out” for the entry of wiring in conduit or NM-cable.

Electrical standard requirements concerning covers for electrical pull boxes, junction boxes, and fittings. OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. Here's how to remove a knockout in order to run wires through the electrical box. Knockouts are partially stamped, quarter-size openings in the electrical boxes.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;The photograph on the right is a knockout in a standard outlet box, that has been pushed in. The hazard with that is if an employee comes up to that, and is plugging something in, and their finger inadvertently goes into that hole that has been knocked out, they can make contact with live electrical parts inside that housing, so that's . Response: Yes, §1910.147 (a) (1) (ii) (D) requires the lockout or tagout of electrical hazards for work on, near, or with conductors or equipment in electric-utilization installations, be done in accordance with §1910, Subpart S.

You may notice a broken, loose, or missing cover on an electrical receptacle or junction box. Or perhaps it’s a missing “knockout” plug on the side of an electrical box. Or, you may occasionally come across an open hole in the face of an electrical breaker panel where one or more electrical breakers are missing.

Since exposure to electricity could cause serious physical harm, OSHA can cite that paragraph for a number of hazards. A search for citations finds things like damaged insulation on wiring, or exposed electrical parts of equipment motors.Many times the opening is an open knockout where a used box is installed and the opening is not properly plugged. The primary issue with covers and canopies is that junction and pull boxes are often left uncovered.

Knockouts are perforated circles cut into the sides, top, bottom, and back of an electric panel box that can be “knocked out” for the entry of wiring in conduit or NM-cable. Electrical standard requirements concerning covers for electrical pull boxes, junction boxes, and fittings. OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations.

open knockouts on outlet boxes

We specialize in the high precision CNC machining of electronic and medical PCB enclosures, aluminum castings, forgings, thin-walled parts, motors, pumps, generator housings, end bells, electrical connectors, and more.Precision CNC Machining Parts Service & Custom CNC Machined Parts Manufacturer. Bergek CNC is good at making prototypes, small-batch, or mass-production customized CNC .

electrical box knockout osha|open knockouts on outlet boxes