components of cnc lathe machine CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or .

A septic tank’s distribution box (or D-box) is a container (typically concrete) that receives the septic tank effluent and re-distributes it into the network of attached drain fields and pipes. To put it simply, its job is to evenly .

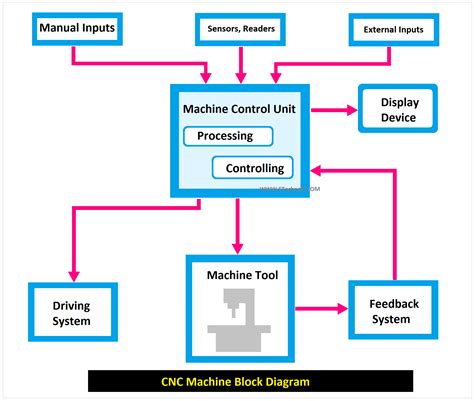

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · cnc machine parts list pdf

3 · cnc machine parts diagram

4 · cnc machine components list

5 · cnc lathe machine diagram

6 · cnc lathe headstock

7 · block diagram of cnc machine

Attach to grade lumber or 5/8" fire-rated board; Use WBAC162 for 1 1/4" and 1 5/8" flanges, and WBAC200 for 2" flanges; Drywall stud (1 1/4" flange): Align top of connector with markings and attach using (4) #8-18 modified truss-head self .

Understanding the key components of a CNC lathe machine is crucial for grasping how these machines achieve such high levels of precision. Let’s break down each part and its role in the process.When it comes to modern manufacturing, nothing beats the precision and . An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.

What are the Key Components of a CNC Lathe Machine? A CNC lathe is an assembly of intricate components, each playing a crucial role in its operation. Understanding these components gives you a deeper insight into .In this comprehensive guide, we will take you on a journey through the inner workings of a CNC lathe machine, providing detailed insights into the various components that make it function . CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or .

Our exploration will cover the essential elements that comprise a CNC lathe machine, starting with the headstock, an integral part that houses the machine’s spindle. We will also examine the lathe bed, the foundation upon . This guide will help you to familiarize the parts of a CNC lathe & turning center and what are types of lathe machine. The CNC lathe and turning centers are a kind of high precision and high-efficiency automatic machine tool.

Understanding the key components of a CNC lathe machine is crucial for grasping how these machines achieve such high levels of precision. Let’s break down each part and its role in the process. Learn more about the parts of a CNC lathe machine and how each part is important. CNC (Computer Numerical Control) lathes are part of the logical progression of precision machining equipment. Like all lathes, they share historical roots with potters’ wheels and primitive woodworking lathes. An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.

schematic diagram of cnc machine

What are the Key Components of a CNC Lathe Machine? A CNC lathe is an assembly of intricate components, each playing a crucial role in its operation. Understanding these components gives you a deeper insight into how these machines achieve such high levels of precision and efficiency.In this comprehensive guide, we will take you on a journey through the inner workings of a CNC lathe machine, providing detailed insights into the various components that make it function seamlessly. CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This . Our exploration will cover the essential elements that comprise a CNC lathe machine, starting with the headstock, an integral part that houses the machine’s spindle. We will also examine the lathe bed, the foundation upon which all other parts are mounted, and the chuck, which holds the workpiece in place.

This guide will help you to familiarize the parts of a CNC lathe & turning center and what are types of lathe machine. The CNC lathe and turning centers are a kind of high precision and high-efficiency automatic machine tool. Whether you’re looking to create complex components for the aerospace industry, parts for medical devices, or simple, yet precise pieces for the automotive sector, CNC lathe machines can handle many tasks: Turning – Cutting a piece of material as it rotates to shape cylindrical parts.

When it comes to modern manufacturing, nothing beats the precision and efficiency of CNC lathe machines. If you’re in need of a quick rundown, here are the main parts of a CNC lathe: CNC lathes have come a long way since their origins, which trace back to primitive woodworking lathes and potters’ wheels.

Understanding the key components of a CNC lathe machine is crucial for grasping how these machines achieve such high levels of precision. Let’s break down each part and its role in the process. Learn more about the parts of a CNC lathe machine and how each part is important. CNC (Computer Numerical Control) lathes are part of the logical progression of precision machining equipment. Like all lathes, they share historical roots with potters’ wheels and primitive woodworking lathes. An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.

What are the Key Components of a CNC Lathe Machine? A CNC lathe is an assembly of intricate components, each playing a crucial role in its operation. Understanding these components gives you a deeper insight into how these machines achieve such high levels of precision and efficiency.In this comprehensive guide, we will take you on a journey through the inner workings of a CNC lathe machine, providing detailed insights into the various components that make it function seamlessly.

CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or angular parts. This . Our exploration will cover the essential elements that comprise a CNC lathe machine, starting with the headstock, an integral part that houses the machine’s spindle. We will also examine the lathe bed, the foundation upon which all other parts are mounted, and the chuck, which holds the workpiece in place.

parts made by cnc machine

This guide will help you to familiarize the parts of a CNC lathe & turning center and what are types of lathe machine. The CNC lathe and turning centers are a kind of high precision and high-efficiency automatic machine tool. Whether you’re looking to create complex components for the aerospace industry, parts for medical devices, or simple, yet precise pieces for the automotive sector, CNC lathe machines can handle many tasks: Turning – Cutting a piece of material as it rotates to shape cylindrical parts.

steel cabinet suppliers

steel cabinet manufacturer chicago

According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal .

components of cnc lathe machine|cnc lathe headstock