biw sheet metal design Learn valuable BIW design tips for sheet metal parts to achieve optimal body structure performance and effectively manage stress and strain. Tin Lunch Boxes HQ: Great Nostalgic & Retro Designed Metal Lunch Boxes! On this site you will find: – The Metal Lunch Boxes Store – Collectors’ Price Guide Reviews. History Of Vintage & Metal Lunch Boxes: – The Best Selling Lunch Box Of All Time! – Ohio Art Lunch Boxes – Lunch Boxes Art By Aladdin Industries

0 · sheet metal biw design

1 · how to design biw parts

2 · biw welding joint design

3 · biw structure design pdf

4 · biw structural design

5 · biw sheet metal design tips

6 · biw sheet metal design questions

7 · biw design guide pdf

Viper Metropolitan Steel Tip Dartboard Cabinet. Dartboard. $184.99. ADD TO CART . On Sale. Viper Championship Dartboard Backboard Cabinet Set. Dartboard. $139.99. WAS: $179.99* .

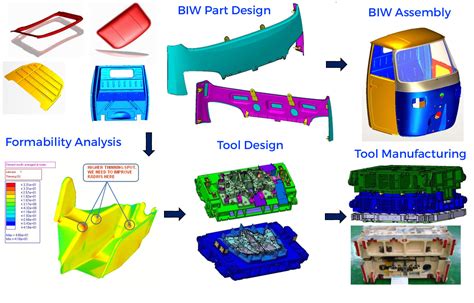

The document provides an introduction to body-in-white (BIW) design, outlining the different types of BIW structures like unibody, space frame, and frame . This video will give you an overview of our Advanced Sheet Metal Design of BIW (Body In White) components using NX CAD or CATIA. In this course you will be u. Learn valuable BIW design tips for sheet metal parts to achieve optimal body structure performance and effectively manage stress and strain. So, here we go - How to design a sheet metal part to deliver a good body structures performance?

The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization.Design of sheet metal forming is traditionally relying on the experience accumulated by tool design engineers through long and costly trial and error experiments. Simple empirical .

Body in White (BIW) refers to the stage of production where sheet metal components of the vehicle are welded together in the automotive manufacturing process. To join the vehicle's main structure together, typically through robotic .ADSL is committed to delivering an agile sheet metal manufacturing solution, supported by comprehensive experience, technology experts, advance tool room for prototype. We aim to build integral relationships with customers, providing . So, here we go — how do we design a sheet metal part to deliver a good body structure performance? Well, if you are looking for a single magical response, I’m afraid to tell you that this answer doesn’t exist.The document provides an introduction to body-in-white (BIW) design, outlining the different types of BIW structures like unibody, space frame, and frame-mounted designs. It also describes the major systems that make up the BIW like the front end, underbody, side body, and closures.

Some stamped metal part design best practices often help to achieve expected body-in-white (BIW) structures performance and prevent potential problems.

sheet metal biw design

This video will give you an overview of our Advanced Sheet Metal Design of BIW (Body In White) components using NX CAD or CATIA. In this course you will be u. Learn valuable BIW design tips for sheet metal parts to achieve optimal body structure performance and effectively manage stress and strain. So, here we go - How to design a sheet metal part to deliver a good body structures performance?The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization.

Design of sheet metal forming is traditionally relying on the experience accumulated by tool design engineers through long and costly trial and error experiments. Simple empirical methods provide some guidelines for cases similar to those on which these methods were developed.

Body in White (BIW) refers to the stage of production where sheet metal components of the vehicle are welded together in the automotive manufacturing process. To join the vehicle's main structure together, typically through robotic welding, laser brazing, MIG welding, MAG welding, spot welding, and riveting, where jigs and fixtures are likely .

ADSL is committed to delivering an agile sheet metal manufacturing solution, supported by comprehensive experience, technology experts, advance tool room for prototype. We aim to build integral relationships with customers, providing them .

how to design biw parts

biw welding joint design

biw structure design pdf

So, here we go — how do we design a sheet metal part to deliver a good body structure performance? Well, if you are looking for a single magical response, I’m afraid to tell you that this answer doesn’t exist.The document provides an introduction to body-in-white (BIW) design, outlining the different types of BIW structures like unibody, space frame, and frame-mounted designs. It also describes the major systems that make up the BIW like the front end, underbody, side body, and closures.

Some stamped metal part design best practices often help to achieve expected body-in-white (BIW) structures performance and prevent potential problems.

This video will give you an overview of our Advanced Sheet Metal Design of BIW (Body In White) components using NX CAD or CATIA. In this course you will be u.

Learn valuable BIW design tips for sheet metal parts to achieve optimal body structure performance and effectively manage stress and strain. So, here we go - How to design a sheet metal part to deliver a good body structures performance?The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization.

Design of sheet metal forming is traditionally relying on the experience accumulated by tool design engineers through long and costly trial and error experiments. Simple empirical methods provide some guidelines for cases similar to those on which these methods were developed.Body in White (BIW) refers to the stage of production where sheet metal components of the vehicle are welded together in the automotive manufacturing process. To join the vehicle's main structure together, typically through robotic welding, laser brazing, MIG welding, MAG welding, spot welding, and riveting, where jigs and fixtures are likely .

round cut in box electrical

ross metal dog boxes

$25.00

biw sheet metal design|how to design biw parts