class 1 div 2 electrical enclosures For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. **NEMA 10. These . high speed twin pallet horizontal machining centre with linear guideways & rotary type pallet changing system. models – hs4000 ii, hs5000 ii

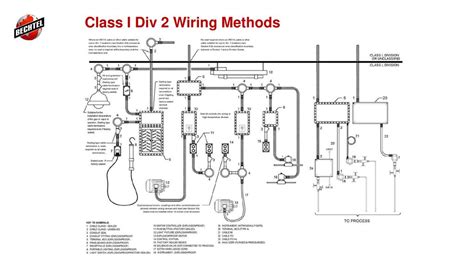

0 · class 1 div 2 wiring

1 · class 1 div 2 specifications

2 · class 1 div 2 rules

3 · class 1 div 2 receptacle

4 · class 1 div 2 nec

5 · class 1 div 2 enclosure requirements

6 · class 1 div 2 distances

7 · class 1 div 2 certification

Each package contains six 1.25 fl.oz. bottles of dimensional fabric paint in trendy color combinations and finishes, and each bottle of paint is equipped with a writer tip for precise placement. Available in a variety of color sets (each sold separately). Non-toxic. Conforms to ASTM D4236. Imported. Let your creativity shine with the Tulip!

The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and .EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX .

Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of .

For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. **NEMA 10. These ..00

class 1 div 2 wiring

Type 1 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment .

Class II devices exclude dust from the enclosure’s interior. When properly installed, a Class II device will not permit arcs, sparks or heat to ignite dust (or a dust cloud) on or Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities .

Understanding the importance of Class 1 Div 2 classification is crucial for professionals in hazardous environments, ensuring the safe operation of electrical equipment. This understanding guides the selection of safe, .

Ingress Protection (IP) codes for electrical enclosures in Class 1/DIV 2 and non-hazardous locations. An IP (Ingress Protection) rating is used mainly by buyers in Europe to specify the .

class 1 div 2 specifications

We recommend electrical enclosures meet or exceed a NEMA rating of Type 4 or Type 4X for use in a Class1 Div2 hazardous location when used with appropriate purge systems.

The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and protection techniques against any risks.EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX certifications.

Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of panels in hazardous locations with purge and pressurization solutions. For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. **NEMA 10. These enclosures are intended to meet the Mine Safety and Health Administration (MSHA), 30 CFR Part 18 (1978). NEMA 11. General-purpose.

Type 1 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt).Class II devices exclude dust from the enclosure’s interior. When properly installed, a Class II device will not permit arcs, sparks or heat to ignite dust (or a dust cloud) on or

Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. Understanding the importance of Class 1 Div 2 classification is crucial for professionals in hazardous environments, ensuring the safe operation of electrical equipment. This understanding guides the selection of safe, compliant devices for industries with elevated risks, like oil and gas or medical sectors.Ingress Protection (IP) codes for electrical enclosures in Class 1/DIV 2 and non-hazardous locations. An IP (Ingress Protection) rating is used mainly by buyers in Europe to specify the extent of protection an electrical enclosure has against environmental conditions. We recommend electrical enclosures meet or exceed a NEMA rating of Type 4 or Type 4X for use in a Class1 Div2 hazardous location when used with appropriate purge systems.

class 1 div 2 rules

The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and protection techniques against any risks.EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX certifications.

Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of panels in hazardous locations with purge and pressurization solutions. For indoor use in Class II, Division 1, Groups E, F, and G hazardous locations according to NFPA 70, this is also referred to as dust-ignition proof. **NEMA 10. These enclosures are intended to meet the Mine Safety and Health Administration (MSHA), 30 CFR Part 18 (1978). NEMA 11. General-purpose.Type 1 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt).Class II devices exclude dust from the enclosure’s interior. When properly installed, a Class II device will not permit arcs, sparks or heat to ignite dust (or a dust cloud) on or

Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. Understanding the importance of Class 1 Div 2 classification is crucial for professionals in hazardous environments, ensuring the safe operation of electrical equipment. This understanding guides the selection of safe, compliant devices for industries with elevated risks, like oil and gas or medical sectors.

cnc machine shop in oman

cnc machine repair toronto

Recessed Outlet/Electrical Box Single Gang, Recessed Outlet Box for Wall Mount TV, Antenna, Phone and Cable TV, Suitable for GFCI Outlet and Standard Outlet, for Old or New Construction 4.5 out of 5 stars

class 1 div 2 electrical enclosures|class 1 div 2 wiring