2t r sheet metal Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary operations and is far more costly. $38.88

0 · sheet metal form height ratio

1 · microsoft word sheet metal design

Though competitor next-generation trucks have opted for aluminum panels and closures over a steel body, Ford on Thursday announced the next-generation 2021 Ford F-150 would carry “a fully boxed high-strength steel frame with a .

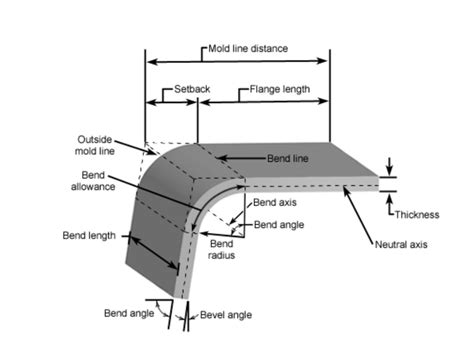

The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake .

Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary . The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .

Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary operations and is far more costly. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. The bend radius refers to the curvature of a bend and is determined by the material type, thickness, and bend angle. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. This article explores the essential principles of sheet metal design, focusing on bending techniques to ensure precision and durability. By the end, you'll understand key strategies to prevent common issues in sheet metal fabrication.

Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Minimum bend radii are typically specified in terms of sheet thickness (t) such as 1t, 2t, 3t, etc. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet.Bend radius (Radii): Sheet metal parts should have a bend radius to avoid cracking. Bend radius (r) should be between one to two times sheet thickness (t): 2t >= r => t

This document provides information on sheet metal design and manufacturing processes. It discusses parameters for sheet metal like thickness and common terminology. It also outlines various sheet metal processes like bending, forming, stamping and piercing. The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary operations and is far more costly.

Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. The bend radius refers to the curvature of a bend and is determined by the material type, thickness, and bend angle.

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. This article explores the essential principles of sheet metal design, focusing on bending techniques to ensure precision and durability. By the end, you'll understand key strategies to prevent common issues in sheet metal fabrication.Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs.

sheet metal form height ratio

Minimum bend radii are typically specified in terms of sheet thickness (t) such as 1t, 2t, 3t, etc. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet.Bend radius (Radii): Sheet metal parts should have a bend radius to avoid cracking. Bend radius (r) should be between one to two times sheet thickness (t): 2t >= r => t

microsoft word sheet metal design

cnc machining grande prairie

cnc machining for sale

Architectural Metal Fabrication is a highly specialized niche where the cliché, form-and-function, really hits the mark. Architectural metal must look visually spectacular while simultaneously perform to the highest fabrication and high quality engineering standards.Shop for-and learn about-Vintage and Antique Dollhouses. Elaborate cabinet-style dollhouses (also spelled as "doll houses"), in which the rooms on one side.

2t r sheet metal|sheet metal form height ratio